Cement is a crucial component in construction projects. Accurate measurement of its setting time is vital for ensuring successful project planning and execution. Knowing the right time to handle, cure, and apply cement-based materials can make all the difference. That is where the test for setting the time of cement comes into play.

This test is an essential procedure that determines the time it takes for cement to reach a particular level of hardness. Understanding this information is critical for professionals in the construction industry, allowing them to make informed decisions about their use of cement.

Key Takeaways:

- The test for the setting time of cement is crucial for accurate measurement of its setting time.

- Knowing the correct setting time of cement is essential for proper handling, curing, and application of cement-based materials.

- The procedure consists of testing the time it takes for cement to reach specific levels of hardness.

- Environmental conditions and cement composition can affect the setting time of cement.

- Achieving accurate results requires proper sample preparation, test conditions, and data recording.

Explaining the Test for Setting Time of Cement

The test for setting the time of cement is an important factor in construction projects as it determines the time for which cement remains plastic and workable. The setting time varies according to the environmental and other factors that can affect the chemical reaction between the water and the cement.

The test for setting time is conducted to ensure that cement is used within the appropriate period to ensure its optimal strength. In this section, we will describe the fundamental procedure of the test for setting time of cement, which is primarily composed of the following steps.

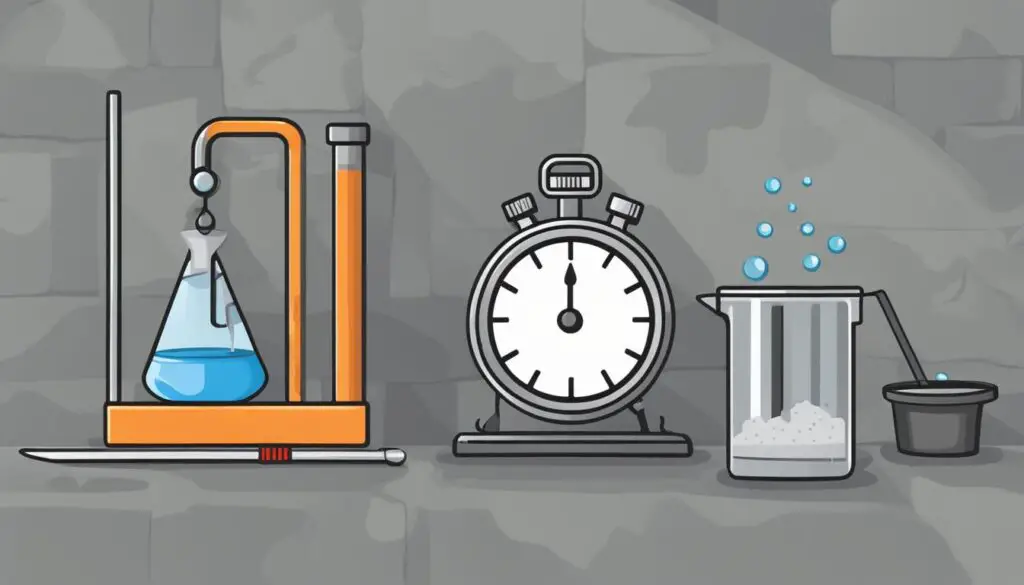

Apparatus:

The apparatus used to conduct the test for setting time includes a Vicat apparatus, a measuring glass, a vessel, and a stopwatch. The Vicat apparatus consists of a movable rod weighing 300gm, which falls freely in its vertical guide, and a nonporous plate with a diameter of 50mm.

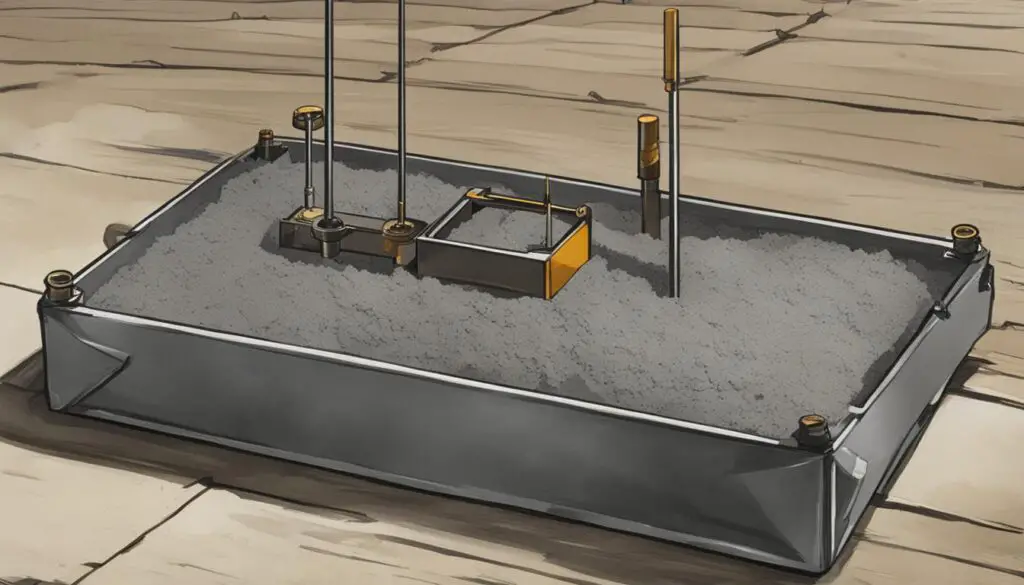

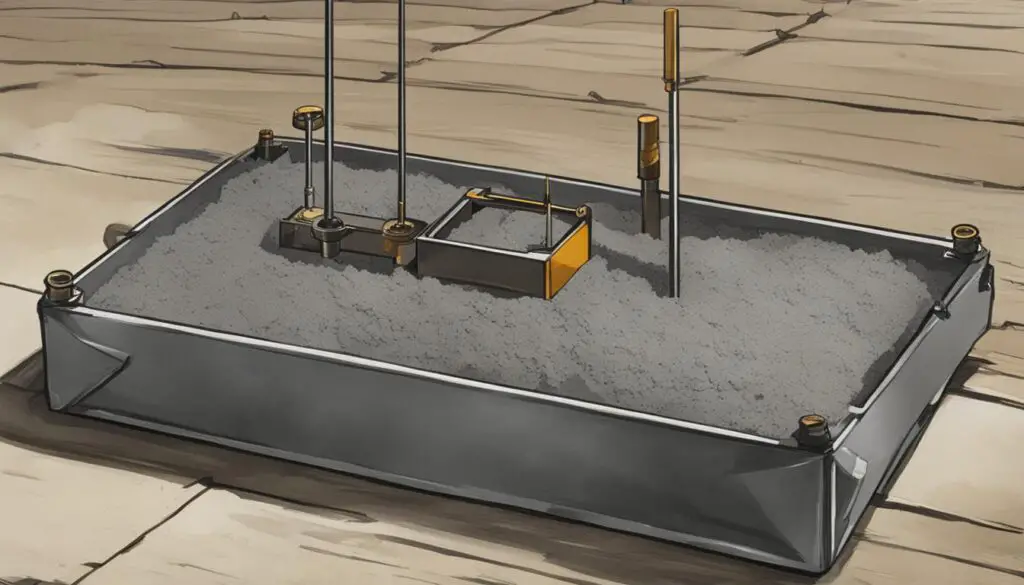

Test specimen:

To ensure the reliability of results, the specimen should be tested within the industry-specific time after preparation. The test specimen is composed of cement and water, in a ratio of 1:3, and is mixed thoroughly. The time between mixing and measuring should be strictly controlled to ensure the accuracy of the result.

Procedure:

- First, prepare the test sample, which is a mixture of cement and water.

- Fill the Vicat apparatus with the sample and use the plunger to softly settle the mixture.

- After that, the test specimen is placed under the rod and the movement of the rod is released.

- The test is conducted with at least three samples of the same mixture and an average is taken of the results.

The accurate procedure of the test for setting time of cement can significantly impact the overall quality of construction projects. Proper testing ensures that cement is used within the appropriate setting period and the construction project stays on schedule.

Understanding the Initial Setting Time of Cement

When it comes to cement, the initial setting time is a crucial factor. It refers to the time from the moment water is added to the cement until the mixture starts to stiffen and lose its plasticity. The initial setting time is significant for construction projects since it determines when the material can be handled or finished before it is set completely.

The initial setting time of cement is determined by conducting a test, which involves preparing a cement paste and measuring the time it takes to reach the initial set. This test for initial setting time is crucial, as it ensures that the cement mixture can set and gain strength at the right time, as per the requirements of the project.

The results of the test for initial setting time also affect the strength of the concrete, which is vital to ensure the safety and longevity of any construction project. It helps determine the ideal time to start curing the concrete and the duration of time required for the curing process.

Therefore, accurately determining the initial setting time of cement is critical for achieving a durable, strong, and reliable structure. This information is useful for construction professionals in India and beyond, as it minimizes risks and errors in building projects.

Determining the Final Setting Time of Cement

After measuring the initial setting time of cement, the next step is to determine the final setting time. This refers to the point in time when the cement paste completely loses its plasticity and hardens, making it unsuitable for application or any form of manipulation.

The final setting time test is conducted similarly to the initial setting time test, with the only difference being the needle used for measurement.

Once the Vicat apparatus needle, weighing 300g and with a cross-sectional area of 1 sq. cm, penetrates the cement paste to a point where it makes contact with the Mould plate, and no further deformation occurs, the final setting time is considered achieved. The time taken for this to happen is recorded as the final setting time of the cement.

It is crucial to accurately determine the final setting time of cement as it significantly affects the strength and durability of the concrete structure. A premature application of the cement-based material before it reaches its final setting point can result in substandard quality and deterioration over time.

In addition, the final setting time test indicates the time frame within which the construction workers should complete the mixing and laying of the concrete mixture. This ensures that the concrete attains its maximum strength and durability, enhancing safety and structural resilience.

As with the initial setting time test, the final setting time is affected by several factors, including temperature, humidity, chemical composition, and water content. Adopting the best practices for accurate testing and ensuring controlled environmental conditions will enhance the reliability and usefulness of the test results.

The Apparatus Used in the Test

For accurate testing of cement setting time, a specific apparatus is required. These include:

| Apparatus | Function |

|---|---|

| Gauging Trowel | Used for mixing cement and water to create a consistent mixture |

| Standard Vicat Apparatus | Consists of a Vicat needle, plunger, and glass plate. Used for measuring the penetration depth of cement paste. |

| Measuring Cylinder | Used for accurate measurement of water required to mix the cement |

| Stopwatch | Used for recording the setting times of the cement at regular intervals |

Each component plays a vital role in determining the setting time of cement accurately. It is essential to ensure the apparatus is in good condition and calibrated to maintain precision. Understanding the functions of each element in the apparatus can aid in successful test execution.

Step-by-Step Procedure for the Test

Conducting a test for setting the time of cement can be easily done by following a simple, step-by-step process. This section provides a detailed procedure that is easy to follow for professionals and beginners alike.

Step 1: Preparation

First, mix the cement and water in the required proportions to form a paste that is uniform and consistent. Use water that is clean and free from any contaminants.

Step 2: Filling the Apparatus

Fill the Vicat apparatus with the prepared cement paste, using a trowel to ensure the surface is even and clean.

Step 3: Placing the Needle

Place the needle on the surface of the paste, allowing it to penetrate to a depth of 5mm. Ensure the needle is vertical and not tilted.

Step 4: Determining Initial Setting Time

Start the timer as soon as the needle penetrates the paste to a depth of 5mm. Check the paste at intervals of 30 seconds until the needle fails to penetrate the paste. The time elapsed from the addition of water to the point where the needle fails to penetrate the paste is the initial setting time of the cement.

Step 5: Determining Final Setting Time

Repeat step 4, but this time use a needle with a larger diameter (10mm). The time elapsed from the addition of water to the point where the needle fails to make an impression on the paste’s surface is the final setting time of the cement.

Overall, following these simple steps can provide accurate and reliable results, ensuring that the setting time of cement is precisely measured.

Factors Affecting Setting Time

The setting time of cement refers to the time taken by the mixture to change from a plastic state to a hardened state. Numerous factors can influence this process, directly or indirectly. Here are a few factors affecting the setting time of cement:

| Factors | Description |

|---|---|

| Temperature | Ambient temperature plays a significant role in controlling the setting time of cement. Higher temperatures accelerate the process, while lower temperatures delay it. Therefore, it is essential to maintain a consistent temperature throughout the curing period. |

| Humidity | The water-cement ratio determines the humidity level required for the cement curing process. Excess moisture can significantly affect the setting time, delaying the hardening process. |

| Type of Cement | The composition and chemical properties of cement significantly influence its setting time. Rapid hardening cement, for instance, sets faster than ordinary Portland cement. |

| Admixtures | Additives such as retardants and accelerators can modify the setting time of cement, making it suitable for specific construction projects. |

By understanding the various factors that impact the setting time of cement, professionals can ensure adequate curing and proper use of cement mixtures.

Importance of Accurate Setting Time Measurement

Accurately measuring the setting time of cement is crucial for any construction project. It ensures the proper handling, curing, and application of cement-based materials, which could affect the overall quality and durability of the structure. A precise understanding of the setting time of cement enables professionals to make informed decisions about the best time to start and finish various construction tasks, allowing for a smooth and efficient project timeline. Moreover, measuring the setting time of cement is necessary for maintaining safety standards on the worksite.

Conducting the test for setting time of cement is the best way to obtain accurate results. It provides detailed information on the initial and final setting time of cement and enables professionals to assess the performance of different cement products. The test for setting time helps in diagnosing any issues with the cement’s composition or environment that could affect the setting time, thus preventing any unintended consequences.

Overall, precise measurement of the setting time of cement offers numerous advantages, including cost savings, durability, safety, and efficiency. Using the setting time test enhances the quality of construction work and allows for better planning, execution, and management of construction projects from start to finish.

Best Practices for Test Accuracy

Accurate testing of cement setting time is crucial in construction projects to ensure the efficient handling and application of cement-based materials. Below are some best practices for conducting reliable and precise tests:

Sample Preparation

Before testing, it is essential to prepare the cement samples carefully. The samples should be stored in airtight containers to maintain their freshness. Moreover, they should be carefully stored under controlled conditions to prevent moisture absorption, which can affect the accuracy of the results.

Test Conditions

The testing conditions, including temperature and humidity, should be accurately recorded and controlled to ensure uniform test results. Any deviations can significantly impact the results and their relevance to the construction projects.

Data Recording

Accurate data recording is essential for reliable results. Technicians should avoid guesswork and ensure that they note down all observations and results accurately, including the initial and final setting times.

The success of any construction project depends on the accuracy of cement setting time. Therefore, it is crucial to follow these best practices for reliable and precise testing while measuring the setting time of cement.”

Applications and Benefits of Setting Time Test

While the setting time test may seem like an additional step in an already busy construction process, its benefits are numerous. This test is critical in determining the amount of time it takes for cement to set and harden, allowing for a more informed approach to construction projects.

One key application of the test includes ensuring the appropriate level of water is mixed with the cement, which can affect how long it takes for the cement to set. Additionally, understanding the setting time of cement can help professionals schedule their work accurately, ensuring that materials are applied at the right time and reducing the chances of rework.

The setting time test also enables better quality control, which can reduce costs and improve the overall durability of the construction project. By accurately measuring the setting time of cement, professionals can identify any issues with the mix, determine when to apply the next layer, and more – all of which can ultimately contribute towards saving time, money, and resources.

It’s important to note that accurate testing can only be achieved by following strict procedures and best practices, which were covered in previous sections of this guide.

Summary

The setting time test for cement may require additional time and effort, but it provides valuable insights that can ultimately lead to more efficient and effective construction projects. By understanding the benefits and applications of this test, professionals can take a more informed approach to their work, resulting in better quality control, reduced rework, and a more durable and long-lasting finished product.

Conclusion

In conclusion, accurate measurement of the setting time of cement is crucial in ensuring the success of construction projects. From understanding the apparatus used and the step-by-step procedure for conducting the test to exploring the factors that can influence the setting time of cement, this article has provided a comprehensive guide to the test for the setting time of cement.

By obtaining reliable results through best practices and adhering to the recommended procedures, professionals in India and beyond can ensure that they are properly handling, curing, and applying cement-based materials. The applications and benefits of the setting time test are vast and can assist in project planning and execution, ultimately saving time, money, and resources.

Professionals need to keep in mind that the accuracy of their results is crucial, and they should always follow the recommended guidelines and best practices. By doing so, they can ensure the success of their construction projects and contribute to the growth and development of India’s infrastructure.

Thanks For the Great Attention!

Good Bye & Take Care

Happy Learning