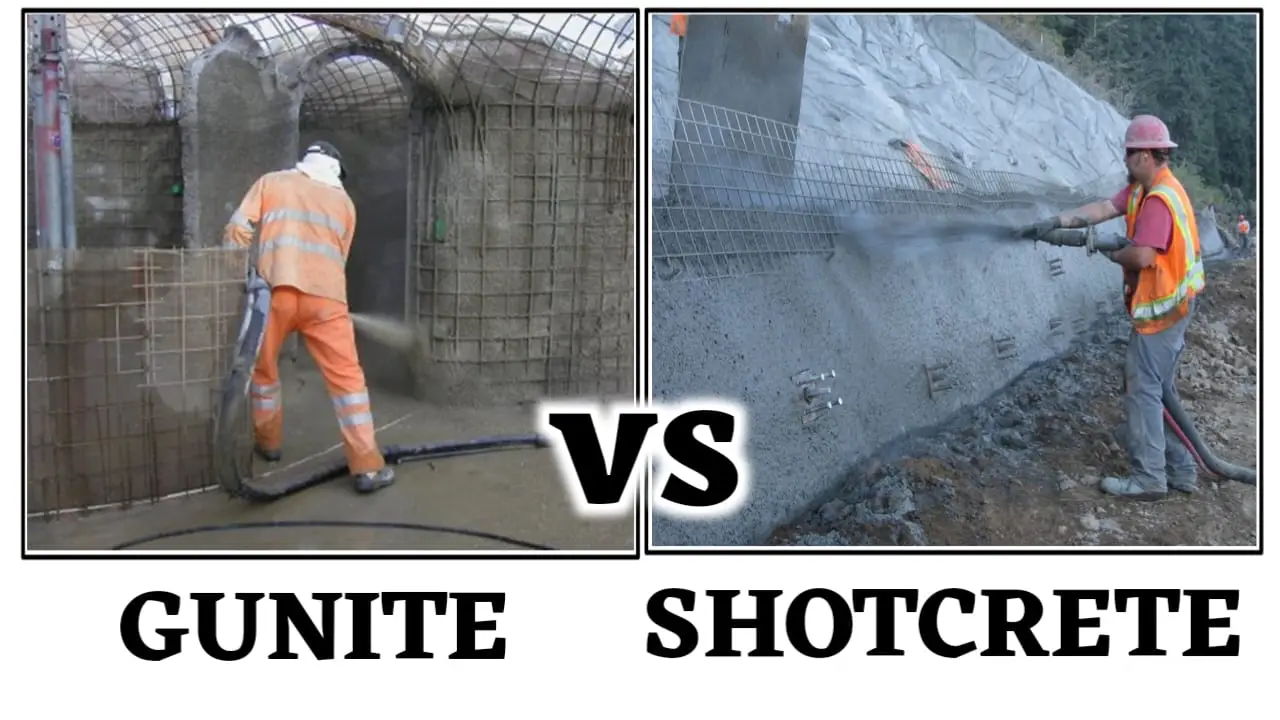

Shotcrete vs Gunite

If you’re working on a construction project, you may have heard about the Shotcrete vs Gunite construction methods. These are both popular methods that offer unique benefits, making it important to understand their differences so that you can make an informed choice that best suits your needs.

Shotcrete vs Gunite have similarities, but they also have significant differences in terms of application, cost, and other factors, which can affect the outcome of your construction project. In this article, we will explore the key differences between shotcrete vs gunite that you need to know to decide which option is the best choice for your needs.

Key Takeaways

- Shotcrete vs gunite offers various benefits, including strength and durability.

- Shotcrete is typically more expensive but requires skilled operators, while gunite is more versatile and rebound is a common issue.

- Shotcrete is suitable for a wide range of applications, including dome construction, retention walls, and slope stabilization.

- Gunite is well-suited for pool construction and foundation repairs, thanks to the material’s durability and precision shaping capabilities.

- The choice between shotcrete vs gunite comes down to a variety of factors such as project requirements, budget, application, and availability of skilled operators.

Introduction

If you are planning a construction project, you may have come across shotcrete vs gunite. These construction methods are commonly used for various applications, each with distinct advantages and disadvantages. Before diving into the details, let’s define shotcrete vs gunite.

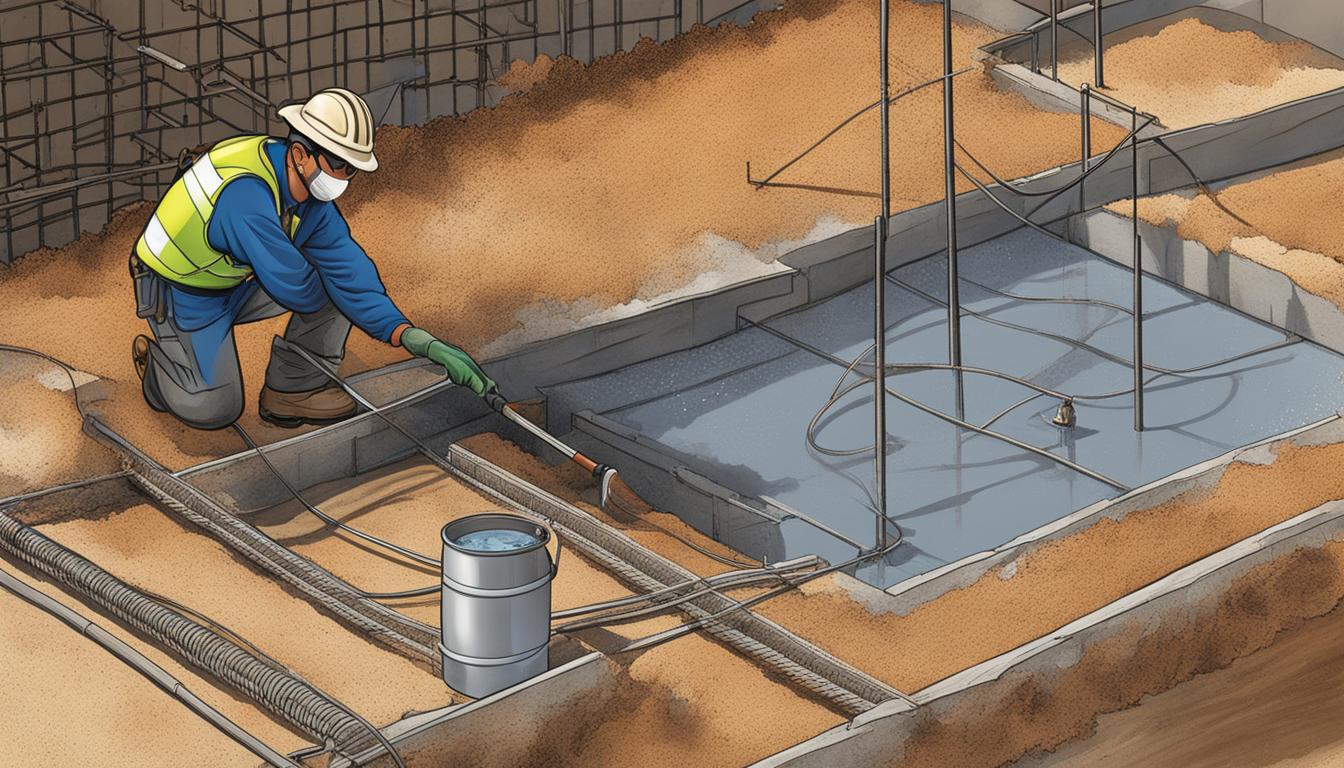

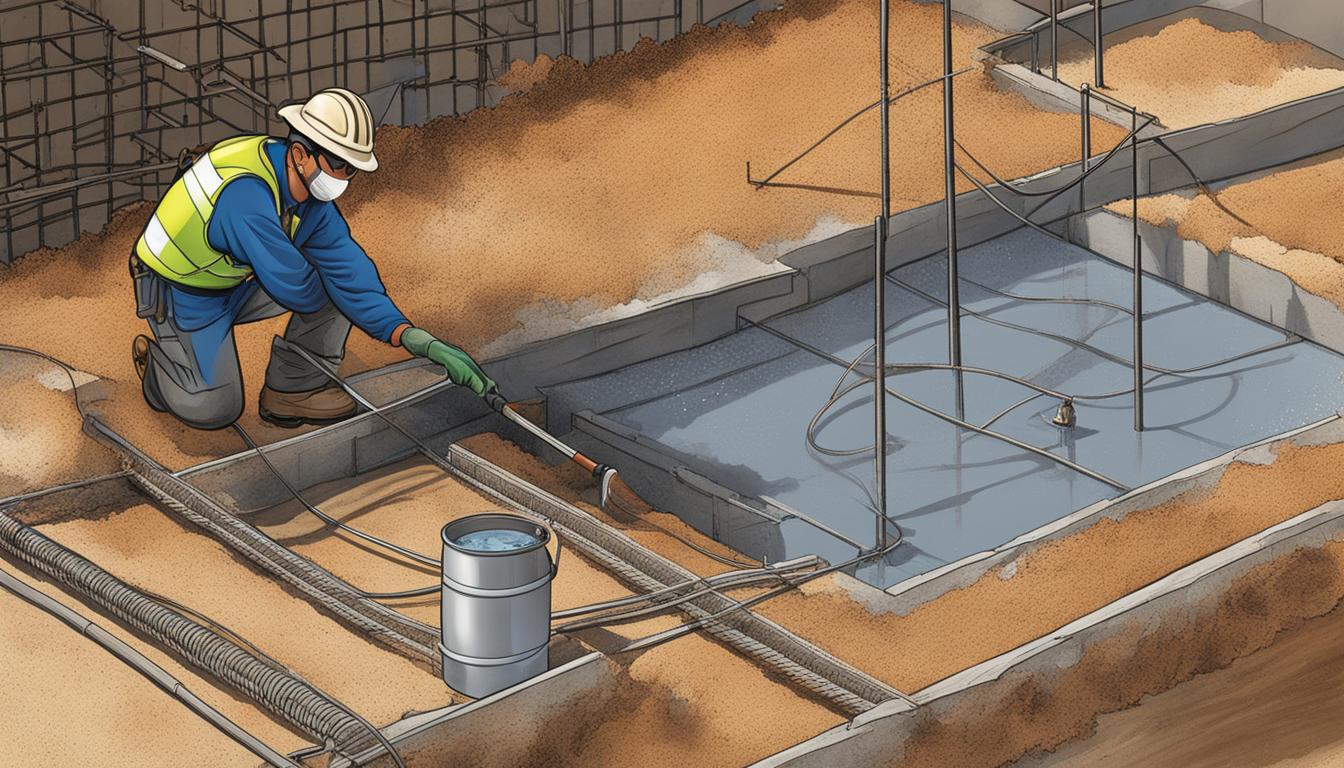

Shotcrete is a construction method where a mixture of cement, aggregates, and water is sprayed onto a surface with compressed air at high velocity. On the other hand, gunite is a construction method that involves spraying a mixture of dry cement and sand, combined with water at the nozzle during application. Both methods offer unique advantages and disadvantages that are important to consider before deciding which one suits your needs best.

“For any construction project, choosing the right construction method is crucial. Understanding the key differences between shotcrete vs gunite can help you make an informed decision.”

What is Shotcrete?

Shotcrete is a construction method that involves spraying a mix of cement, aggregates, and water onto a surface at high velocity using compressed air. This process creates a strong and durable material that adheres well to various surfaces. Shotcrete is a popular choice for construction projects where conventional concrete placement is not feasible or cost-effective.

However, shotcrete can be more expensive than traditional concrete due to the specialized equipment needed. Additionally, skilled operators are required to ensure proper spraying technique and material consistency.

Advantages of Shotcrete

Shotcrete offers several advantages over traditional construction methods. Its high strength and durability make it suitable for a wide range of applications, including:

- Dome Construction

- Retention Walls

- Tunneling

- Artificial Ponds

- Mining Applications

- Dikes and Dams

- Ditches and Channels

- Water Tanks and Ponds

- Slope Stabilization

The versatility of shotcrete allows it to conform to any shape or design. Shotcrete can be applied to vertical, overhead, and curved surfaces, making it a flexible option for construction projects.

Disadvantages of Shotcrete

Despite its numerous advantages, shotcrete also has some disadvantages. One of the main drawbacks is the higher cost compared to traditional concrete. The application process requires specialized equipment and skilled operators, increasing the overall project cost.

Another drawback of shotcrete is that it can be difficult to control the consistency of the mix, leading to potential quality issues during the application process.

Advantage of Shotcrete

If you’re looking for a construction method that offers high strength and durability, then shotcrete is the way to go. Shotcrete provides several benefits over other construction methods, making it a popular choice for various applications.

Benefits of Shotcrete

- Strength: Shotcrete provides exceptional strength due to the compressed air application process, which results in a dense, consolidated material with excellent bonding properties. This makes shotcrete an ideal choice for structures that require high strength, such as tunnels, dams, and retaining walls.

- Durability: Shotcrete is resistant to weathering, erosion, and chemical attack, offering long-term durability and extended service life, even in harsh environmental conditions.

- Adaptability: One of the greatest advantages of shotcrete is its adaptability. It can be applied to both vertical and horizontal surfaces and can cover areas that are hard to reach with traditional concrete, providing versatile solutions for many applications.

- Reduced labor cost: Compared to other construction methods, shotcrete requires less labor, as it can be applied quickly and easily, resulting in reduced labor costs for project owners.

These advantages make shotcrete an excellent choice for various construction projects. Its suitability for specialized applications, such as dome construction, artificial ponds, and mining applications, makes it a preferred choice for many construction professionals.

Disadvantages of Shotcrete

While shotcrete offers some clear benefits over traditional concrete, it’s important to consider the potential drawbacks before deciding whether it’s the right choice for your construction project.

One significant disadvantage of shotcrete is its higher cost. Because the application process is more complex than standard concrete, it typically requires more specialized equipment and skilled operators. This can make it a more expensive option for construction projects with tight budgets.

Another potential disadvantage of shotcrete is the need for skilled operators. Because the mix is sprayed onto surfaces at high velocity, operators must ensure proper spraying technique and material consistency. If not done correctly, the strength and durability of the resulting shotcrete can be compromised.

In conclusion, while shotcrete may provide outstanding strength, durability, and versatility, it may not be suitable for all construction projects. We recommend weighing the benefits and drawbacks carefully to make an informed decision for your specific needs.

What is Gunite?

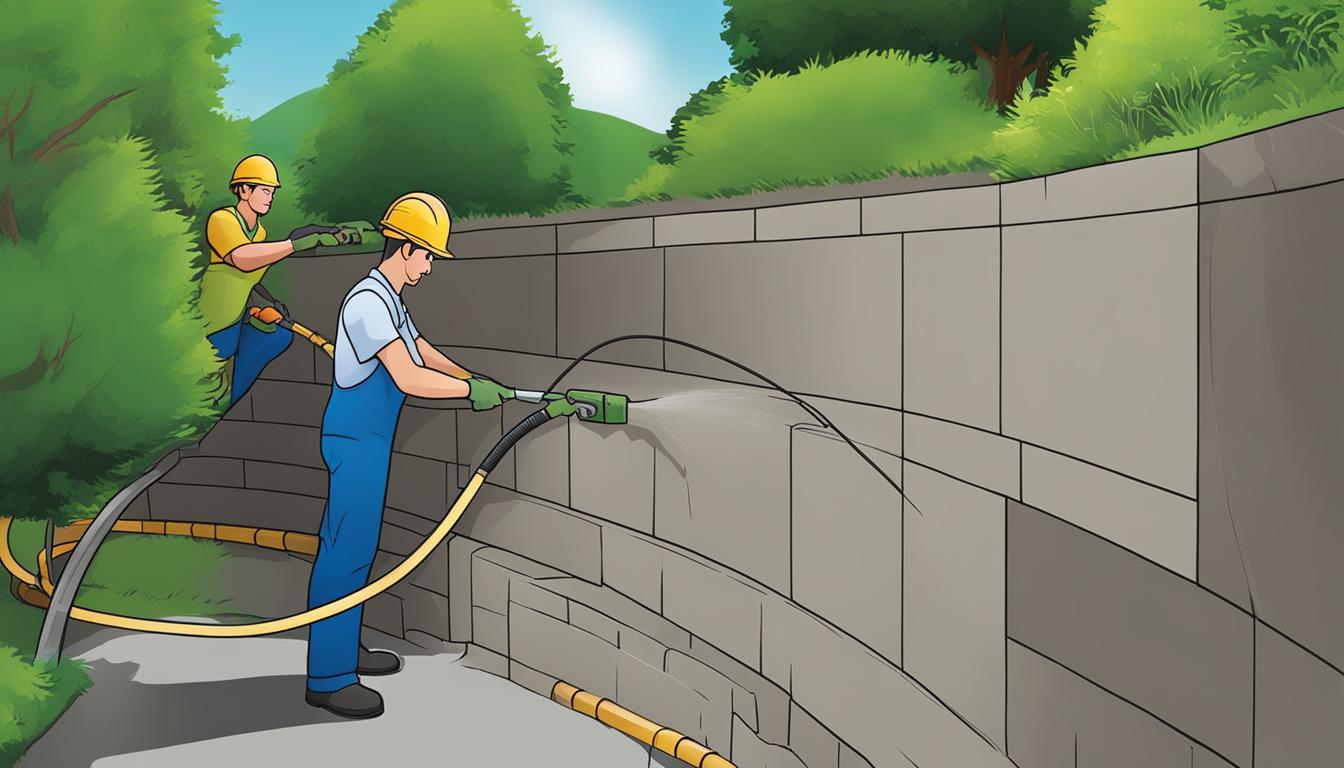

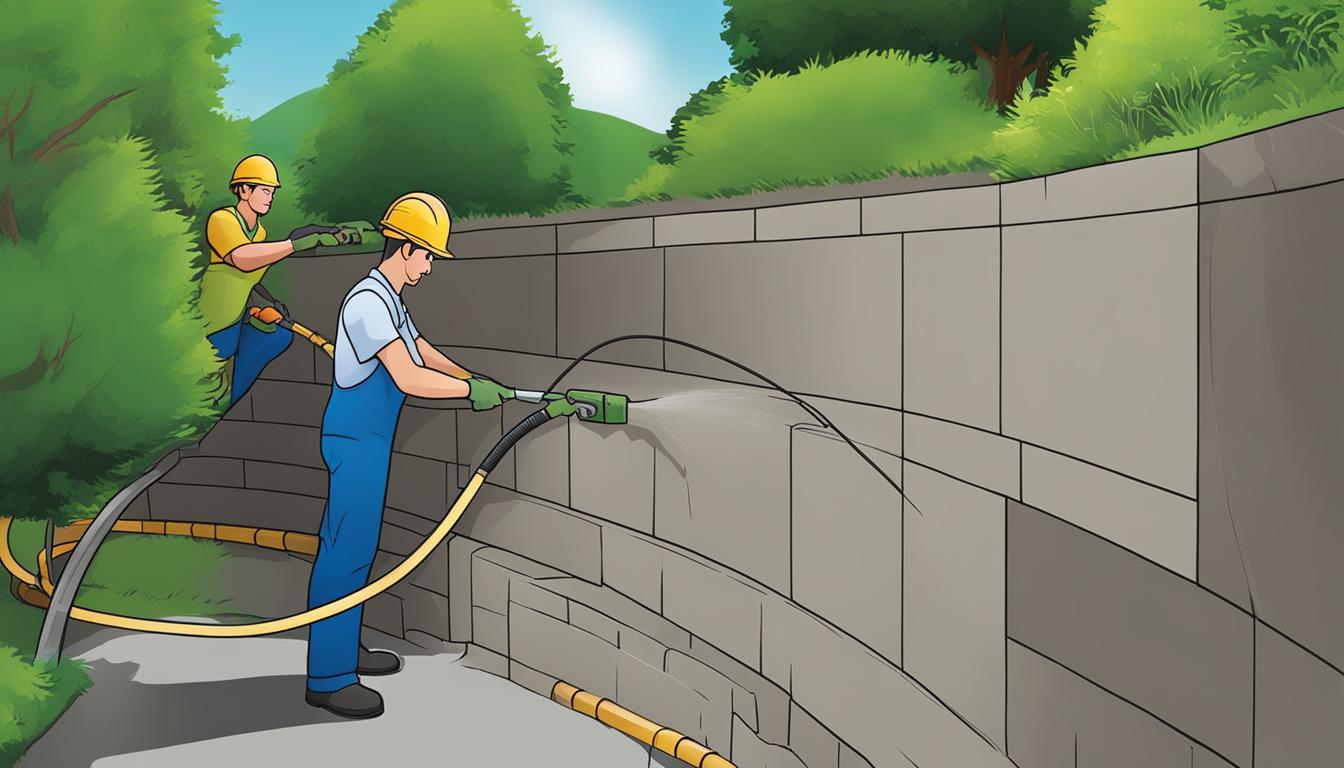

Gunite is a popular construction method that involves spraying a mixture of cement, sand, and water onto a surface using compressed air. The dry-mixed ingredients are combined with water at the nozzle during application, which creates a strong and durable material that adheres well to various surfaces.

The advantages of gunite include its versatility, which allows for precise shaping, and its durability, which makes it ideal for various applications. However, there are also some disadvantages to consider.

One of the main disadvantages of gunite is rebound, which can lead to material wastage during application. Skilled operators are necessary to control the rebound and ensure consistent application.

Gunite is particularly well-suited for pool construction, where its precise shaping and the ability to endure constant exposure to water and chemicals make it an excellent choice.

Advantages of Guniting

Guniting is a construction technique with several advantages that make it appealing for applications such as pool construction, foundation repairs, and tunnel linings. One of its primary benefits is versatility: Guniting enables precise shaping, which is ideal for complex or curved surfaces that need careful attention to detail.

Another advantage of Guniting is the strength and durability of the material created. The high-quality cement mixture produced via Guniting ensures the longevity and resilience of structures built with this method.

If you are considering a construction project that requires durability and long-lasting structural integrity, Guniting is an excellent choice. By utilizing this method, you will ensure not only the excellent finishing of your project but also minimize the need for frequent repairs in the future.

Example:

“We choose to use guniting for our tunnel linings because of its strength and resistance to wear and tear. The precise shaping also allowed us to customize the lining to fit our specific requirements.”

– Sarah Jones, Construction Engineer at ABC Inc.

Disadvantages of Guniting

While Guniting offers several advantages, it has a few notable drawbacks that you should be aware of as well. One of the main issues is rebound, which refers to the material that bounces back during application, leading to waste and inefficiency.

To minimize rebound, skilled operators are necessary to control the spray effectively. Without proper training and expertise, inexperienced operators may struggle to maintain control and precision, resulting in uneven applications, further waste, and an inferior finished product.

Overall, while Guniting is a versatile and often effective construction method, it does require a certain degree of expertise to produce high-quality results. Make sure to work with skilled operators who can minimize issues like rebound and ensure consistent and precise applications.

Applications of Shotcrete

Shotcrete is a versatile construction method that finds extensive applications in various construction projects. Whether you need to create a dome, retaining walls, or stabilize slopes, shotcrete can be an excellent choice. Here are some of the most common applications of shotcrete:

Dome construction

Shotcrete is an excellent choice for constructing domes due to its ability to conform to complex shapes. Domes are found in many structures such as sports facilities, museums, and churches. Shotcrete can help to create a sturdy and durable dome that can withstand severe weather conditions.

Retaining walls

Shotcrete can be used to construct retaining walls that hold back soil or rock. Retaining walls are often used to create usable terraced landscapes, and prevent soil erosion and slope failures. Shotcrete retaining walls can also improve the aesthetic value of landscapes.

Tunneling

Shotcrete is highly used in tunnel construction as it forms a strong foundation material that can withstand both compression and tension stresses. Intermediate walls, shafts, and liners can also be created using shotcrete.

Artificial ponds

Shotcrete is ideal for creating artificial ponds for various uses such as landscaping, aquaculture, and recreational purposes. The material’s strength and durability make it resistant to water and chemical erosion, ensuring that the artificial pond remains intact for a long time.

Mining applications

Shotcrete is used extensively in mining applications for ground support, tunnel lining, and secondary mining support. The shotcrete mixture can be tailored for different mining activities to offer reliable and robust support.

Dikes and dams, ditches, and channels

Shotcrete can be used in the construction of dikes and dams, creating ditches and channels for flood protection and control. The material’s strength prevents it from being affected by moving water and is highly resistant to water-induced erosion. Shotcrete structures can last longer than traditional concrete structures in waterlogged areas.

Water tanks and ponds

Shotcrete can be used to construct water tanks and ponds for water storage and supply. Shotcrete’s water-resistant properties make it an ideal construction material for water tanks and ponds in areas with limited freshwater supplies.

Slope Stabilization

Shotcrete can be used for slope stabilization in areas where the terrain is steep and prone to landslides. Shotcrete reduces the risk of soil erosion and preserves the landscape’s aesthetics while ensuring the slope’s stability.

Applications of Gunite

Gunite is a versatile construction method that works particularly well in certain applications. One of its most common uses is in pool construction. The gunite material allows for precise shaping, making it ideal for creating unique pool designs that conform to your specific vision. Gunite is also exceptionally durable, with the ability to withstand constant exposure to chemicals and water, ensuring your pool will last for years to come.

In addition to pool construction, gunite is also utilized for foundation repairs. Its strength and durability make it a sound choice for repairing existing foundations or creating new ones. The application process involves spraying gunite onto the surface, creating a thick and robust layer that can withstand significant weight and pressure.

Tunnel linings are another common use for gunite. Its excellent strength and durability make it ideal for creating tunnels that will withstand the test of time. The gunite application process is well-suited for tunnel linings, providing a seamless and robust layer that will stand up to the constant wear and tear of heavy use.

“Gunite provided the perfect solution for our pool construction project. It allowed us to create a custom pool design that truly fit our needs and vision, and we know it will last for years to come.”

Explaining 10 Basic Differences

Shotcrete vs gunite are both popular construction methods, often used interchangeably. However, there are ten fundamental differences between the two. By understanding these differences, you can make a well-informed decision on which method works best for your construction project.

1. Materials

The primary difference between shotcrete vs gunite lies in the materials used. Shotcrete includes a mixture of cement, water, and coarse and fine aggregates applied pneumatically. Gunite, on the other hand, involves premixing the cement and sand dry before adding water to the nozzle.

2. Water Cement Ratio

Gunite typically requires more water than shotcrete, meaning that the water-cement ratio is higher. This can lead to a weaker concrete surface, making shotcrete a better choice if a stronger surface is needed.

3. Application Process

Shotcrete is applied wet with a high-pressure hose, while gunite is applied dry with the inclusion of water at the nozzle. Shotcrete requires skilled operators, and the process is more expensive than gunite.

4. Compressive Strength

While both shotcrete vs gunite have good compressive strength, shotcrete has a higher strength than gunite, making it ideal for more demanding construction applications.

| Compressive Strength, Psi (lb/in2) | |

|---|---|

| Shotcrete | 4,500-7,500 |

| Gunite | 2,000-5,500 |

5. Elastic Modulus

The elastic modulus of shotcrete is higher than gunite. This means that shotcrete can better resist deformation over time, making it well-suited to use in situations where settling may occur, such as tunnels and mines.

| Elastic Modulus, (lb/in2) | |

|---|---|

| Shotcrete | 1.5-4×106 |

| Gunite | 9×105-1.5×106 |

6. Rebound

Rebound refers to the amount of material that bounces back during application. With shotcrete, rebound can account for 15-50% of the material sprayed. In contrast, gunite has less rebound, wasting less material compared to shotcrete.

7. Smoothness of the Surface

Shotcrete provides a smoother surface compared to gunite. If a perfectly smooth surface is needed, then shotcrete is the better option.

8. Construction Site Access

In situations where construction site access is restricted, shotcrete is more advantageous due to its ability to be used with robots or long hoses.

9. Control

In terms of how well each method is controlled, there is no significant difference. Both require skilled operators and regular checking during application to ensure proper consistency.

10. Cost

Shotcrete is generally more expensive than gunite. This is due to the more rigorous application process, longer setup time, and need for skilled operators.

After reviewing these differences, you can make an informed decision on which method to use for your construction project. While both methods have their advantages and disadvantages, the final choice will come down to your specific project requirements, budget, and available skilled workers.

Shotcrete vs Gunite

Should You Choose Shotcrete vs Gunite for Your Pool Construction?

When it comes to building a pool, choosing between gunite and shotcrete can be a tough decision. Both methods have their unique advantages and drawbacks, and the choice will ultimately depend on your specific needs and preferences in pool construction.

First and foremost, consider the strength and durability of the materials. Shotcrete is known for its high strength and durability, making it a popular choice for large-scale projects such as building retaining walls or tunnel linings. On the other hand, gunite is often favored for smaller-scale projects like residential pool construction due to its strength and flexibility.

The method of application is also a crucial factor to consider. Shotcrete is typically applied using a wet mix that is sprayed onto surfaces at high velocity, resulting in a solid, consistent finish. Gunite, on the other hand, is applied through a dry mix, which is mixed with water on-site before being sprayed. This gives the installer greater control over the consistency of the mix and allows for more precise shaping.

One potential downside of gunite is the possibility of rebound during application, where a portion of the material bounces back, causing material waste. With shotcrete, the material adheres well to surfaces, ensuring minimal waste during application.

Ultimately, the choice between gunite and shotcrete for your pool construction project may come down to the availability of skilled operators in your area. Shotcrete requires experienced operators who can ensure proper spraying technique and material consistency, while gunite is generally more forgiving in the hands of less experienced operators.

Before making a final decision, it’s important to weigh the factors carefully, evaluate your specific needs and preferences, and consult an experienced professional in pool construction. By doing so, you can be confident that you’ve made the right choice for your pool construction project.

Conclusion

When it comes to selecting shotcrete vs gunite for your construction project, it is crucial to evaluate your specific needs properly. Both methods have distinct advantages and disadvantages, and the final choice should depend on project requirements, budget, and availability of skilled operators.

In summary, understanding the differences between shotcrete vs gunite is the first step to making an informed decision. Shotcrete is ideal for applications requiring high strength and durability, such as dome construction, retaining walls, and tunneling. On the other hand, gunite is versatile and particularly well-suited for swimming pool construction, foundation repairs, and tunnel linings due to its precise shaping and excellent durability.

Before choosing between shotcrete vs gunite, it is essential to assess different factors such as cost, rebound, and skilled operators. Remember, both methods require trained professionals who can ensure proper application and consistent results.

In conclusion, by following the guidelines mentioned in this article, you can rest assured that you are making an informed decision and selecting the best construction method for your project.

By doing so, you can aim to complete your construction project successfully, safely, and efficiently.

Thanks For the Great Attention!

Good Bye & Take Care

Happy Learning

Also, Read,

1000sqft House Plinth Beam Cost

1500Sqft House Construction Cost In 2024

FAQ

What is the difference between shotcrete vs gunite?

Shotcrete vs gunite are both construction methods that involve spraying a mixture of cement, aggregates, and water onto surfaces. The key difference lies in the mixing process. Shotcrete uses a wet mix that is pre-mixed before it is pumped through a nozzle and sprayed onto the surface. Gunite, on the other hand, uses a dry mix of cement and sand that is combined with water at the nozzle during application.

What are the advantages of shotcrete?

Shotcrete offers several advantages. It is known for its high strength and durability, making it suitable for a wide range of applications. Shotcrete can be applied to various surfaces, including vertical or overhead areas, and it adheres well to existing structures. It is also a versatile construction method that can be used in dome construction, retention walls, tunneling, artificial ponds, mining applications, dikes and dams, ditches and channels, water tanks and ponds, and slope stabilization.

What are the disadvantages of shotcrete?

One disadvantage of shotcrete is its higher cost compared to traditional concrete. The application process requires skilled operators who can ensure proper spraying technique and material consistency. Additionally, the use of shotcrete may require specialized equipment and permits, adding to the overall project cost.

What is the advantage of gunite?

Gunite offers several advantages for construction projects. It provides excellent strength and durability, making it suitable for applications such as pool construction, foundation repairs, and tunnel linings. Gunite also allows for precise shaping, making it ideal for curved or complex surfaces.

What are the disadvantages of gunite?

One disadvantage of gunite is rebound, where a portion of the sprayed material bounces back during application, leading to material waste. Skilled operators are necessary to control the rebound and ensure consistent application. Additionally, the dry-mixing process of gunite may require more on-site preparation and equipment.

What are the applications of shotcrete?

Shotcrete finds extensive applications in dome construction, retaining walls, tunneling, creating artificial ponds, mining applications, constructing dikes and dams, building ditches and channels, creating water tanks and ponds, and stabilizing slopes.

What are the applications of gunite?

Gunite is commonly used in pool construction due to its versatility and ability to endure exposure to chemicals and water. It is also utilized for foundation repairs and tunnel linings.

What are some basic differences between Shotcrete vs Gunite?

The ten basic differences between shotcrete vs gunite are the mixing process, water content, rebound, material consistency, equipment requirements, application capabilities, surface preparation, project cost, skilled operators, and construction timeline.

Should I choose Gunite or Shotcrete for my pool?

The choice between Shotcrete vs Gunite for your pool construction depends on various factors, including your budget, desired shape and finish, project timeline, and available skilled operators. It is advisable to consult with a professional pool contractor to determine the best option for your specific needs.

Related video

Shotcrete vs Gunite

Excellent post about shotcrete versus gunite.