15 Important & Basic Civil Engineering Interview Questions and Answers

If you are preparing for a civil engineering interview, then you must be aware that the competition for this field is fierce. You need to demonstrate your knowledge and expertise to stand out to potential employers. To help you prepare for your upcoming interview, we have compiled a list of 75 important and basic civil engineering interview questions and answers. By studying and understanding these questions, you will be better equipped to impress your potential employer and secure your desired position.

In this section, we will provide you with a comprehensive list of questions that cover a wide range of topics, including structural analysis, concreting, soil mechanics, and more. By thoroughly studying and preparing your answers to these questions, you will improve your chances of acing your upcoming interview. Whether you are a recent graduate or a seasoned professional, this list of questions will help you enhance your knowledge and showcase your expertise in the field.

So, let’s get started with the most important and basic civil engineering interview questions and answers!

What are Bending Moment (BM) and shear Force (SF) – Explain

If you’re preparing for a civil engineering interview, it’s crucial to understand the concepts of bending moment (BM) and shear force (SF). In simple terms, BM is the algebraic sum of moments caused by all external forces acting on a structure, while SF is the algebraic sum of the vertical forces acting on a structure at any point. To put it another way, BM represents the bending effect of forces on a structure, while SF represents the cutting effect caused by forces acting perpendicular to the length of a structure.

In structural analysis, a common method used to calculate and visualize BM and SF is to construct a shear force and bending moment diagram. A bending moment diagram shows variations in the bending moment along the length of a beam, while a shear force diagram shows variations in the shear force along the same length. These diagrams are critical for designing and analyzing various structural elements such as beams, trusses, and frames.

Why are BM and SF important in civil engineering?

Understanding these concepts is vital for assessing the structural integrity and safety of a building or bridge. Analyzing BM and SF helps engineers determine the required cross-section and reinforcement of structural components to prevent failure and ensure long-term durability. Additionally, it is essential to consider and mitigate the effects of BM and SF on a structure during construction and maintenance.

What are the units of BM and SF?

BM is measured in units of force times length, such as N-m or lb-ft. SF is measured in units of force per unit of cross-sectional area, such as N/m or lb/ft.

Steps Involved in the Concreting Process – Explain

In civil engineering, concreting is a critical process that involves a series of steps to ensure that the concrete is of high quality and durability. Understanding the concreting process is crucial for civil engineers, especially for those preparing for an interview that focuses on this topic.

The step-by-step process involved in concreting includes:

| Step | Description |

|---|---|

| 1 | Preparation of Ingredients |

|

Also called batching, this step is the process of obtaining all the necessary components for the concrete mixture. The materials used in this process include cement, water, aggregates, and admixtures, which are mixed in predetermined proportions based on the required strength and performance of the concrete. |

|

| 2 | Mixing |

|

The mixing process entails thoroughly combining the components to form a homogeneous and consistent mixture. Various methods can be used to achieve this, including hand mixing, machine mixing, or ready-mix concrete. The important aspect is ensuring that all materials are mixed correctly and adequately to prevent inconsistencies in strength and durability. |

|

| 3 | Transportation |

|

After mixing, the concrete is transported to the construction site using various modes of transportation, including trucks, conveyor belts, and pumps. This step is critical to ensure that the concrete remains workable and fresh until placement. |

|

| 4 | Placement |

|

The concrete is then placed in the desired location using various techniques such as pouring, pumping, or placing it using a crane. Proper placement is fundamental to ensure that the concrete maintains its desired shape and structural integrity. |

|

| 5 | Curing |

|

Finally, the concrete is cured by providing the right conditions for it to set and harden to its full strength and durability. Various methods can be used to cure concrete, including wet curing, membrane curing, and steam curing. Curing is essential to achieve maximum strength and durability of the concrete. |

|

Gaining a thorough understanding of the concreting process, including the steps outlined above, is crucial for success in interviews related to civil engineering. You must grasp the process’s nuances and intricacies and be able to describe the process’s technical aspects to demonstrate your expertise in the field.

Various Methods of Concrete Curing – Brief Description

In civil engineering, curing is an essential process to ensure the required strength and durability of concrete structures. Several methods are employed for concrete curing; the most common ones are:

- Water Curing

- Membrane Curing

- Steam Curing

- Chemical Curing

- Carbon Dioxide Curing

Water curing involves providing the concrete surface with adequate moisture to continue the hydration process. Membrane curing involves covering the concrete surface with a waterproof material to retain moisture. Steam curing involves speeding up the hardening process by supplying steam to the surface. Chemical curing entails using curing compounds or sealers on the surface. Carbon dioxide curing involves passing carbon dioxide through the concrete surface to promote curing.

Each curing method has its advantages and disadvantages. The choice of the curing method depends on several factors such as ambient conditions, desired strength, and the construction schedule.

Keep in mind that an adequate curing method is crucial to ensure the long-term durability of concrete structures.

Minimum Curing Period in Civil Engineering

Concrete structures are crucial for modern construction projects. Still, their durability and performance are heavily dependent on the curing process’s quality and duration. Therefore, it’s essential to understand the appropriate minimum curing period for concrete structures.

In general, the minimum curing period for concrete structures can range from 7 to 14 days, depending on various factors such as the type of cement used, the concrete mix design, and the ambient temperature and humidity levels.

During this period, it’s crucial to ensure the concrete structure remains adequately moist and doesn’t dry out excessively. This is because moisture is essential for the chemical reactions that occur during the concrete curing process, which ultimately determines the strength and durability of the concrete.

However, it’s worth noting that a longer curing period can enhance the concrete structure’s performance. For instance, curing for 28 days can increase the compressive strength of the concrete structure significantly.

It’s crucial to have a thorough understanding of the curing process to ensure that the concrete structure meets the desired strength and durability requirements. Therefore, make sure to prepare for your civil engineering interview by studying the minimum curing period and its importance in concrete structures.

Understanding M25 Concrete

If you’re preparing for a civil engineering interview, it’s important to be familiar with M25 concrete. This type of concrete is commonly used in construction projects due to its high strength and durability.

M25 concrete has a compressive strength of 25 megapascals (MPa) after 28 days of setting. The mix proportion for M25 concrete is 1:1:2, which means one part cement, one part fine aggregates, and two parts coarse aggregates.

This grade of concrete is suitable for a variety of construction applications, including the construction of bridges, buildings, and heavy-duty pavements.

By understanding M25 concrete’s properties, mix proportion, and applications, you’ll be better equipped to answer civil engineering interview questions. Make sure to study and familiarize yourself with this common type of concrete before your interview.

Water-Cement Ratio and Its Relationship to Concrete Strength

Understanding the water-cement ratio is crucial in civil engineering interviews. The water-cement ratio refers to the ratio of water to cement used in making concrete. It can greatly affect the workability, strength, and durability of the concrete. A higher water-cement ratio means more water is used in the mixture, resulting in weaker concrete.

The concrete strength is directly proportional to the water-cement ratio. As the ratio decreases, the strength of the concrete increases. Therefore, using the right water-cement ratio is important in maintaining the desired concrete strength. For example, for a standard M25 concrete mix, the recommended water-cement ratio is 0.5.

It is essential to note that the water-cement ratio should be properly measured and maintained during the entire concrete mixing process. Any variation or negligence can significantly affect the strength and durability of the concrete structure.

Importance of Water-Cement Ratio: Table

| Water-Cement Ratio | Concrete Strength |

|---|---|

| 0.60 | 10 MPa |

| 0.50 | 20 MPa |

| 0.45 | 30 MPa |

| 0.40 | 40 MPa |

Referencing the table above, it is evident that the concrete strength increases as the water-cement ratio decreases. For instance, a concrete mix with a water-cement ratio of 0.40 results in a 40 MPa strength, while a mix with a ratio of 0.60 only yields 10 MPa. This highlights the crucial role of a proper water-cement ratio and reinforces the importance of this concept in civil engineering.

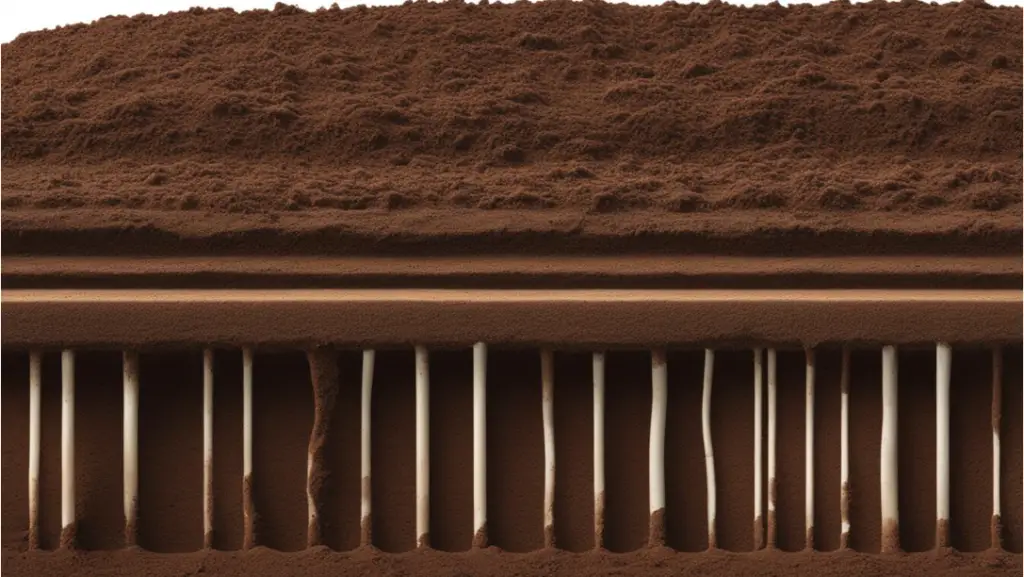

Bearing Capacity of Soil – Definition and Significance

In civil engineering, the bearing capacity of soil refers to the maximum capacity of soil that can support the load from a structure above it.

The significance of bearing capacity lies in its determination of the safety and feasibility of constructing a structure at a particular location.

Factors such as soil composition, groundwater level, and the weight of the structure are taken into account to calculate the bearing capacity of the soil.

During your civil engineering interview, you may be asked questions related to the bearing capacity of the soil. Ensure you have a strong understanding of this important concept to impress your potential employer.

One way to showcase your knowledge is by using a table to present different soil types and their corresponding bearing capacities.

| Soil Type | Bearing Capacity (tons/sq.ft) |

|---|---|

| Clay Soil | 3 – 5 |

| Sandy Soil | 2 – 3 |

| Rocky Soil | 10 – 20 |

Understanding the bearing capacity of soil is integral to civil engineering and the safe construction of infrastructure. Use this knowledge to excel in your civil engineering interview.

Increasing the Bearing Capacity of Soil

As a civil engineer, you understand the significance of stable and safe foundation design. That’s where increasing the bearing capacity of soil comes into play. Here are three different techniques you can implement to increase soil-bearing capacity:

- Compaction: A simple and effective method of increasing the bearing capacity of soil. The soil is compacted by mechanical means, either by vibrating rollers or rammers, until the desired bearing capacity is achieved.

- Soil Stabilization: A chemical or physical treatment process is used to alter the soil’s characteristics and improve its bearing capacity. Chemical stabilization involves adding substances such as lime, cement, or fly ash to the soil to increase its strength and stability. Physical stabilization, on the other hand, involves adding particles to the soil to alter its structure.

- Geosynthetics: Geosynthetics are synthetic materials used to reinforce or stabilize soil. When laid beneath the soil, geosynthetics limit the soil’s movement and improve its bearing capacity.

Implementing any of these methods will boost the soil’s strength and stability, allowing you to design a foundation that can safely bear the weight of the structure.

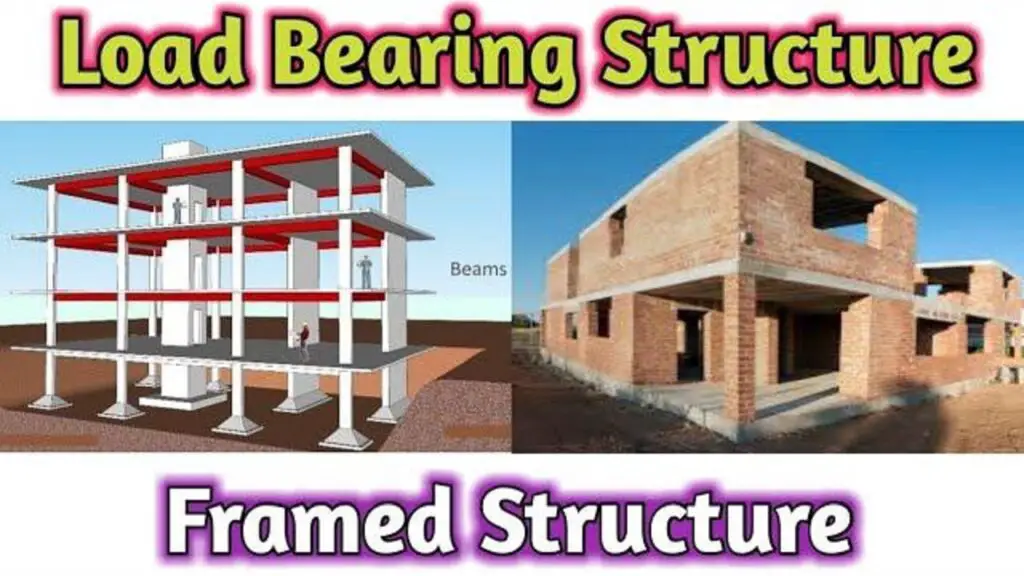

Different Types of Foundations in Civil Engineering

If you’re preparing for a civil engineering interview, you must have an in-depth understanding of the various types of foundations used in construction. Foundations are essential as they support the load of the structure and transfer it to the underlying soil. Different types of foundations are suitable for different construction scenarios, depending on various factors such as soil type, location, climate, and structure type.

Let’s take a look at some of the commonly used types of foundations:

1. Shallow Foundations

Shallow foundations, also known as surface foundations, are used when the depth of the underlying soil is adequate to support the structure’s load. These foundations are suitable for small and simple structures such as residential houses, light commercial buildings, and low-rise structures. Examples of shallow foundations include strip footings, isolated footings, and raft foundations.

2. Deep Foundations

Deep foundations are used when the underlying soil is too weak or the structure’s load is too heavy for shallow foundations. These foundations extend deep into the soil to transfer the load to a stronger layer underground. Examples of deep foundations include pile foundations, drilled shafts, and caissons.

3. Tension Pile Foundations

Tension pile foundations are used when the structure needs to resist uplift forces due to soil liquefaction or high groundwater levels. These piles extend deep into the soil and are anchored to the lower dense soil layer to resist uplift forces. Examples of tension pile foundations include driven piles, augured piles, and micro piles.

4. Caisson Foundations

Caisson foundations, also known as drilled pier foundations, are used when the underlying soil is too soft, and the structure’s load is heavy. These foundations are cylindrical and are drilled into the soil to a specified depth. Structural steel or reinforced concrete is used to construct the caissons.

Understanding the different types of foundations is crucial for civil engineers, as they need to choose the appropriate foundation type based on various site-specific factors. During your interview, be prepared to discuss the advantages and applications of different types of foundations, and how they can be used to provide stable and safe support for construction structures.

Moment of Inertia and Its Importance in Structural Engineering

Moment of inertia is a vital concept in structural engineering, which plays a crucial role in designing structural components. It is the resistance offered by an object to changes in its rotational motion. In simpler terms, it is the measure of how much an object opposes a change in its axis of rotation. The moment of inertia is relevant to the civil engineering industry in many ways.

In structural analysis, it is used to determine the distribution of axial forces and bending moments in different structural components. The moment of inertia is a significant factor in calculating the bending stress in beams and columns, which helps engineers choose appropriate materials for sustainable and safe construction.

Without a clear understanding of the moment of inertia, it is impossible to design and analyze complex structures like bridges, dams, and high-rise buildings. It is essential to have strong fundamentals in the concept of moment of inertia to excel in structural engineering professional roles.

As a candidate seeking a career in civil engineering, it would be wise to prepare yourself to handle interview questions regarding the moment of inertia. Here is an example civil engineering interview question to give you an idea of what to expect:

| Civil Engineering Interview Question: |

What is a moment of inertia? |

|---|---|

| Sample Answer: | In civil engineering, moment of inertia refers to the measure of a beam’s or column’s ability to resist bending. It is a critical factor in the design and analysis of structural components. Without a clear understanding of the moment of inertia, it is impossible to determine the distribution of axial forces and bending moments in different structural components, which can lead to unsafe construction practices. |

By comprehending the concept of the moment of inertia, you will be able to showcase your skills and knowledge during your civil engineering interview.

Determining the Specific Gravity of Cement

Specific gravity is an essential property used to determine the quality and composition of cement in construction projects. The specific gravity of cement is defined as the ratio of the mass of a given volume of cement to the mass of an equal volume of water at the same temperature. Understanding this property is crucial for quality control and material selection in construction projects.

The specific gravity of cement can be determined using two methods:

- The bottle method

- The pycnometer method

The Bottle Method

In this method, a specific gravity bottle is used to determine the specific gravity of cement. The bottle should be clean and dry and have a stopper fitted with a capillary tube. The bottle is first filled with water up to the mark, and the weight of the bottle is recorded. The bottle is then emptied and filled with the dry cement to the same mark, and the weight of the bottle and cement is measured. The specific gravity of cement can be calculated using the formula:

W1

= Weight of cement-filled bottle

W2

= Weight of empty bottle

W3

= Weight of water-filled bottle

The specific gravity of cement is usually between 3.1 to 3.6. Proper testing is essential to ensure precise values and reliable results.

The Pycnometer Method

The pycnometer method is another reliable way of determining the specific gravity of cement. The pycnometer is first filled with water, and its weight is recorded. The pycnometer is then emptied, dried, and filled with dry cement. The weight of the pycnometer and cement is measured. The pycnometer is then topped up with water, and the weight of the filled pycnometer is recorded. The specific gravity of cement can be calculated using the formula:

W1

= Weight of dry cement

W2

= Weight of pycnometer + water + cement

W3

= Weight of pycnometer + water

Overall, the specific gravity of cement is a crucial property used to determine its quality, composition, and reliability in various construction projects. Accurate testing and proper construction practices can ensure the optimal performance and longevity of cement structures.

Density of 1 Cum Cement – Calculation and Importance

In civil engineering, density is a crucial parameter that helps determine various properties of materials. Cement, being an essential component in concrete structures, is no exception. Calculating the density of 1 cubic meter of cement is a straightforward process that involves dividing the mass of cement by its volume. The density of cement varies with its grade and ranges from 300 kg/m3 to 1900 kg/m3.

The importance of density in cement cannot be overstated, as it directly affects the performance and strength of concrete structures. A higher density indicates a higher proportion of cement particles in a given volume, resulting in a stronger and more durable concrete mixture. It also affects the workability and setting time of cement, influencing construction practices and quality control. Ensuring the appropriate density of cement is crucial for maintaining the structural integrity of buildings and infrastructure.

Example Calculation of Density of Cement

| Parameter | Value |

|---|---|

| Mass of cement | 1440 kg |

| Volume of cement | 1 m3 |

| Density of cement | 1440 kg/m3 |

In this example, the mass of cement is 1440 kg, and its volume is 1 m3. Dividing the mass by the volume gives us the density of cement, which is 1440 kg/m3.

As a civil engineering aspirant, understanding the density of cement and its calculations is essential for acing your interview. Ensure that you are familiar with this concept to impress your potential employers and demonstrate your knowledge in the field.

Causes of Building Collapse – Understanding Safety Hazards

Building collapse is a serious issue that can result in significant damage to property and loss of life. As a civil engineer, it’s crucial to understand the root causes of these incidents to ensure safe and reliable construction practices.

Some of the most common building collapse causes include:

- Poor design and structural failure

- Foundation and excavation failures

- Construction errors and inadequate supervision

- Overloading and exceeding design limits

- Environmental hazards like earthquakes, floods, and lightning strikes

- Lack of maintenance and structural degradation over time

It’s important to note that building collapse incidents can result from a combination of these factors. Therefore, implementing comprehensive safety measures during all phases of a construction project is vital to prevent these incidents.

As a civil engineering job aspirant, you should be familiar with the safety procedures and guidelines put in place to ensure safe construction. These safety precautions may include:

- Thorough site inspections and quality controls

- Use of quality materials and equipment

- Regular maintenance and inspections of existing structures

- Proper training and supervision of construction workers

- Incorporating safety factors into the design and construction phases

By understanding the causes of building collapses and implementing the appropriate safety measures, civil engineers can ensure that their constructions remain safe, stable, and durable in the long term.

Bar Bending Schedule (BBS) Preparation and Importance

If you’re preparing for a civil engineering interview, it’s crucial to understand the process of preparing a bar bending schedule (BBS) and its importance in reinforced concrete structures.

BBS is a comprehensive list that provides details about the location, size, shape, and quantity of steel reinforcement in a concrete structure. Understanding BBS is essential for ensuring accurate construction execution, as it helps contractors and construction personnel assess the required amount of steel for a project, reduce project costs, and minimize delays.

To prepare a BBS, the structural drawings of a concrete structure are carefully analyzed to identify the steel reinforcements’ specifications and requirements. These are then tabulated in a detailed chart that includes the steel bar mark, diameter, cutting length, number of pieces required, and weight. In addition to providing detailed information about reinforcements, BBS also helps in determining the required cutting length, bending shapes, and weight of steel reinforcements, making it an essential tool for construction projects.

In summary, understanding the process and importance of preparing a bar bending schedule (BBS) is vital for success in civil engineering construction. Demonstrating your knowledge of BBS can set you apart from other candidates and impress interviewers with your preparation and understanding of essential construction practices.

Conclusion

Congratulations, you have reached the end of this informative article on civil engineering interview questions and answers. The comprehensive list of questions covered in this article will undoubtedly help you prepare for your upcoming interview. It is essential to note that, in addition to possessing a thorough understanding of the technical concepts, you should also communicate confidently and effectively during your interview.

Remember to present yourself professionally and showcase your passion for civil engineering to your potential employer. With the knowledge gained from this article and your dedication, you are undoubtedly more than capable of securing your desired civil engineering position. Good luck!

Thanks For the Great Attention!

Also, Read

1000Sqft house construction cost in 2022

thank you for sharing this blog.