Difference between AAC Block and Red Clay Bricks

Introduction

(Autoclaved Aerated Concrete) AAC block and red clay bricks are two different types of building materials with distinct characteristics.

AAC blocks are made from a mixture of cement, lime, sand, water, and a small amount of aluminum powder. The mixture is poured into molds and then cured with high-pressure steam. The result is a lightweight, cellular concrete block with a porous structure. AAC blocks have good insulation properties, high strength, and are resistant to fire, pests, and mold.

On the other hand, red clay bricks are made by firing clay in a kiln. They are dense, solid blocks with a uniform shape and size. Red clay bricks have good compressive strength and are durable, but they are not as good at insulating as AAC blocks. They are also more susceptible to damage from moisture, pests, and fire.

In summary, AAC blocks are lightweight, porous, and have good insulation properties, while red clay bricks are dense, solid, and have good compressive strength. The choice between these two materials depends on the specific requirements of the building project, such as the climate, location, and type of construction.

What Are The Major Differences Between AAC Block And Red Clay Bricks

|

Sl. |

Parameters |

AAC Block |

Red Clay Brick |

|

1 |

Material Composition |

a mixture of cement, lime, sand, water, and aluminum powder |

natural clay |

|

2 |

Density |

550-650 kg/m³ |

1600-1800 kg/m³ |

|

3 |

Compressive Strength |

3.5 to 7.5 N/mm² |

3.5 to 5 N/mm² |

|

4 |

Thermal insulation |

Better than Red Clay Bricks |

Less than AAC Block |

|

5 |

Cost |

Expensive But reduce the overall cost of construction |

Chipper |

|

6 |

Weight |

Light Weight |

Heavier than AAC Block |

|

7 |

Sound insulation |

Better |

Not Better |

|

8 |

Drying shrinkage |

Less ( 0.4% ) |

More ( 0.8% ) |

Material Composition of AAC Block And Red Clay Bricks

1). Composition of AAC Block

AAC blocks are a type of lightweight, precast, foam concrete building material. They are primarily composed of the following materials –

Fly Ash: Fly ash is a fine, powdery substance that is produced as a byproduct of burning pulverized coal in power plants. It is used as a substitute for Portland cement in the production of AAC blocks.

Cement: Cement acts as a binder and provides strength to the AAC blocks. It is usually Portland cement, which is a commonly used type of cement.

Lime: Lime is used to enhance the workability and plasticity of the AAC block mixture. It also contributes to the overall strength of the blocks.

Sand: Sand is an essential component of AAC blocks. It provides the required texture, reduces the density of the blocks, and improves thermal insulation.

Related Video:- AAC Block and Red Clay Bricks

Water: Water is necessary for the hydration process of cement, which helps in the formation of the AAC blocks.

Aluminum Powder: Aluminum powder reacts with lime and water to produce hydrogen gas, which creates air bubbles in the mixture. These air bubbles contribute to the lightweight and insulating properties of AAC blocks.

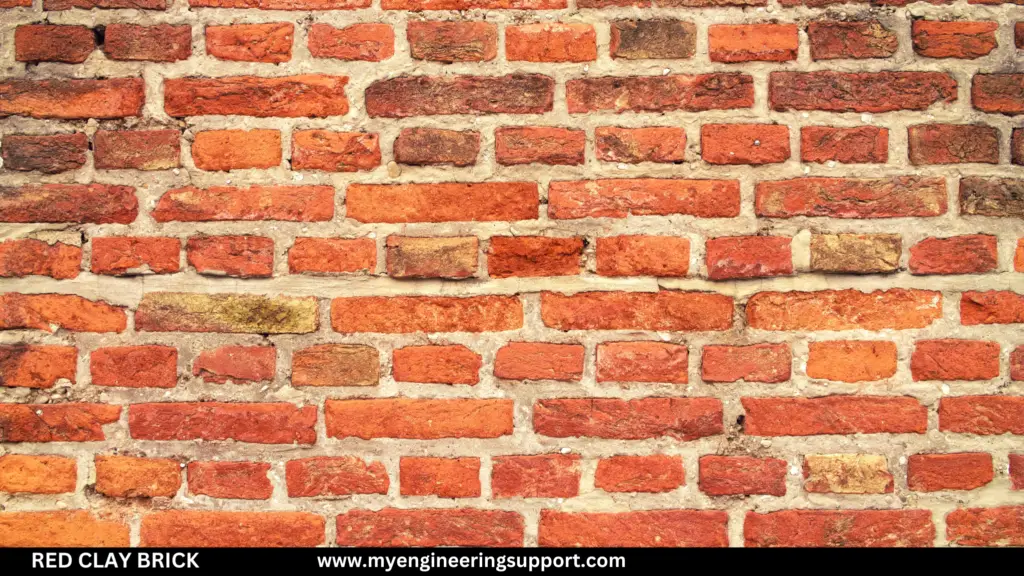

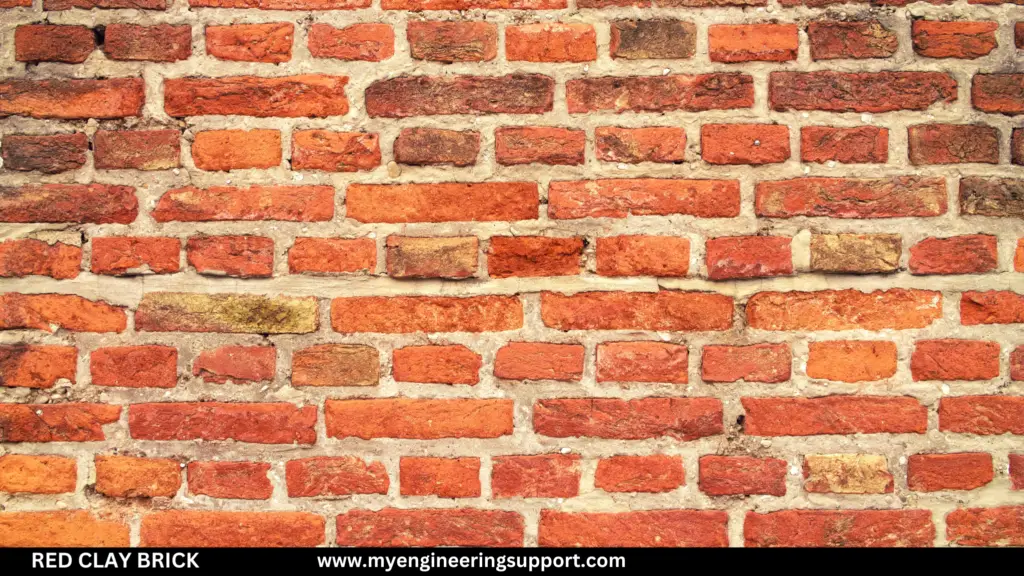

Composition of Red Clay Bricks

Red clay bricks are traditional building materials made from clay that is fired in a kiln. The composition of red clay bricks typically includes the following materials:

Clay: Clay is the primary raw material used in the production of red clay bricks. It is a natural, fine-grained soil that contains a high proportion of aluminum silicates. Clay provides plasticity and workability to the brick mixture.

Sand: Sand is added to the clay mixture to improve its workability and reduce shrinkage during the firing process. It also helps in controlling the texture and strength of the bricks.

Water: Water is used to moisten the clay and sand mixture, making it malleable and suitable for molding into bricks.

Firing Additives: Various additives, such as sawdust or rice husks, may be included in the mixture to enhance the firing process. These additives burn away during firing, creating small voids that increase the insulation properties of the bricks.

Coloring Agents: Sometimes, iron oxide or other coloring agents are added to the mixture to give the bricks their characteristic red color.

After the raw materials are mixed, the brick mixture is molded into the desired shape and then fired in a kiln at high temperatures, typically between 900 to 1,200 degrees Celsius (1,650 to 2,200 degrees Fahrenheit), to harden and strengthen the bricks.

Related Video:- AAC Block and Red Clay Bricks

2). Density

The density of materials can vary depending on the specific type and manufacturing process. However, I can provide you with approximate density ranges for AAC block and red clay bricks based on commonly used standards.

The density of AAC Block

The density of AAC blocks typically ranges from 500 to 900 kg/m³. However, the most commonly used density for AAC blocks is around 600 to 800 kg/m³.

The density of Red Clay Bricks

Red clay bricks generally have a higher density compared to AAC blocks. The density of red clay bricks typically ranges from 1,800 to 2,200 kg/m³.

It’s important to note that these values are approximate ranges and may vary depending on the specific manufacturer and geographical location. If you require precise density values, it is recommended to consult the specifications provided by the manufacturer of the particular AAC Block and Red Clay Bricks you are interested in.

3). Thermal insulation

Thermal insulation refers to the ability of a material to reduce the transfer of heat between two surfaces or areas with different temperatures. Both AAC block and red clay bricks have different thermal insulation properties. These are discussed here –

Thermal insulation of AAC Blocks

AAC blocks are lightweight, precast building materials made from natural raw materials such as sand, cement, lime, gypsum, water, and a small amount of aluminum powder. During the manufacturing process, the blocks are subjected to autoclaving, which creates air pockets in the material, giving them a cellular structure.

AAC blocks have excellent thermal insulation properties due to the presence of these air pockets within the material. The air pockets act as insulators, reducing the transfer of heat. The thermal conductivity of AAC blocks is generally lower than that of traditional clay bricks, which means they provide better insulation.

The specific thermal insulation properties of AAC blocks can vary depending on the density of the blocks. Lower-density blocks tend to offer better insulation. AAC blocks typically have thermal conductivity values ranging from 0.1 to 0.2 W/m·K, which indicates their ability to resist heat transfer.

Thermal insulation of Red Clay Bricks

Red clay bricks are traditional building materials made from clay, which is molded and then fired in a kiln. The firing process gives the bricks their characteristic red color and makes them durable and sturdy.

Compared to AAC blocks, red clay bricks have lower thermal insulation properties. Clay bricks are denser and have fewer air pockets within the material, which allows for greater heat transfer. Consequently, they have higher thermal conductivity values, usually ranging from 0.6 to 1.0 W/m·K.

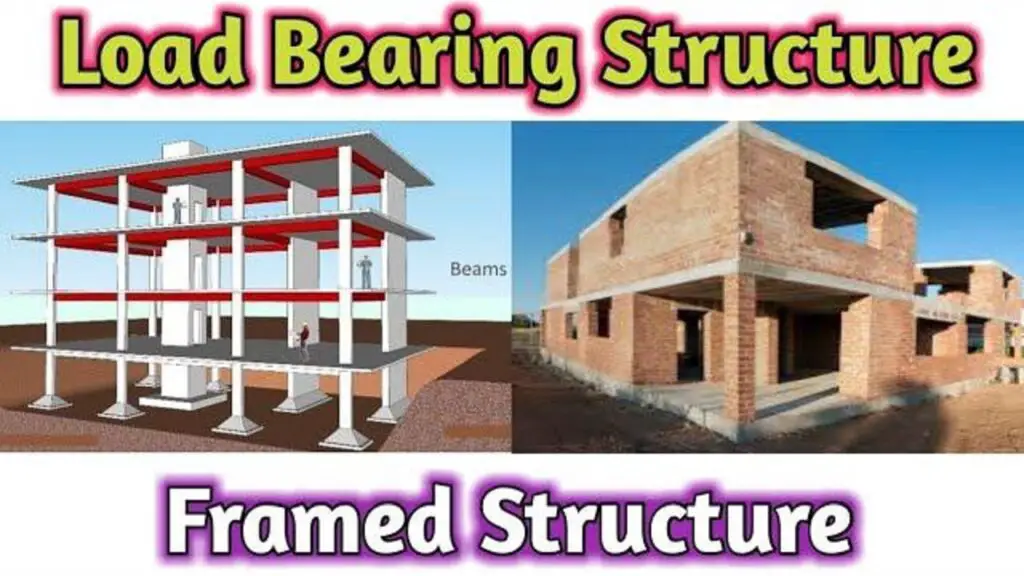

While red clay bricks may not provide the same level of thermal insulation as AAC blocks, they have other advantages, such as high compressive strength and durability. These properties make them suitable for load-bearing applications in construction.

In summary, when it comes to thermal insulation, AAC blocks generally outperform red clay bricks due to their lower thermal conductivity. However, the choice between the two materials should consider other factors like structural requirements, cost, availability, and local building codes and regulations. Consulting with a structural engineer or architect can help determine the best choice for your specific project.

4). Cost

AAC blocks are typically more expensive than Red clay bricks, but their lightweight and easy-to-use properties can offset some of this cost by reducing construction time and labor costs.

The cost of AAC blocks and red clay bricks can vary depending on various factors such as location, supplier, quantity purchased, and current market conditions.

5). Size

AAC blocks are available in different sizes, which include:

- 600mm x 200mm x 50 mm

- 600mm x 200mm x 75 mm

- 600mm x 200mm x 100 mm

- 600mm x 200mm x 150 mm

- 600mm x 200mm x 200 mm

- 600mm x 200mm x 230 mm

- 600mm x 200mm x 250 mm

- 600mm x 200mm x 300 mm

Red Clay Bricks are available in sizes of 225 mm (length) x 115 mm (width) X 75 mm (Height).

6). Workability

Autoclaved Aerated Concrete blocks are lighter weight with higher strength which offers superior workability across all construction projects and requires less labor force. This eventually lessens labor costs enabling a good amount of cost savings at scale. When using AAC blocks, the number of joints is less which again results in a considerable savings of mortar as well as boosting construction speed, unlike the red bricks.

7). Sustainability

AAC blocks are considered to be more environmentally friendly than red clay bricks because they use less material and energy in their production process. Additionally, AAC blocks can be easily recycled, while red clay bricks cannot.

8). Properties of AAC Block And Red Clay Brick

AAC block and red clay bricks are two commonly used building materials. Let’s discuss their Properties individually

Properties of AAC Blocks

AAC blocks are lightweight, precast concrete blocks composed of fine aggregates, cement, lime, and aluminum powder. They undergo a curing process in an autoclave, resulting in a porous structure with air pockets. Here are some properties of AAC blocks

i). Strength

AAC blocks have good compressive strength, typically ranging from 3 to 7 N/mm². This strength is sufficient for most construction purposes.

ii). Resistance to Fire

AAC blocks offer excellent fire resistance due to their inorganic composition. They are classified as fire-resistant materials and can withstand high temperatures for a considerable duration.

iii). Moisture Resistance

AAC blocks have low water absorption, which makes them resistant to moisture-related problems such as cracking, efflorescence, and fungal growth.

iv). Termite and Pest Resistance

AAC blocks are inorganic and do not provide a food source for termites or pests, making them resistant to termite damage.

v). Longevity

When properly installed and maintained, AAC blocks have a long lifespan. They are known for their durability and resistance to weathering.

Properties of Red Clay Bricks

Red clay bricks are traditional building materials made from clay and fired in a kiln. They have been used for centuries in construction. Here are some durability aspects of red clay bricks:

i). Strength

Red clay bricks have high compressive strength, typically ranging from 7 to 15 N/mm², depending on the manufacturing process and brick quality.

ii). Resistance to Fire

Red clay bricks provide good fire resistance. They are non-combustible and can withstand high temperatures without significant structural damage.

iii). Moisture Resistance

Clay bricks have a moderate level of water absorption. They can absorb moisture, but with proper mortar and damp-proofing measures, their susceptibility to moisture-related issues can be minimized.

Related Video:- AAC Block and Red Clay Bricks

iv). Termite and Pest Resistance

Red clay bricks are organic materials and can be susceptible to termite infestation if not properly treated or protected.

v). Longevity

Red clay bricks have a long lifespan, and many historic structures made of clay bricks stand today as a testament to their durability. However, their longevity can be influenced by factors such as the quality of clay, the firing process, and maintenance.

Overall, both AAC Block and Red Clay Bricks are durable building materials. AAC blocks offer advantages such as lighter weight, better thermal insulation, and higher precision in size and shape. Red clay bricks, on the other hand, have a long-standing reputation and aesthetic appeal. The choice between them often depends on factors like project requirements, cost, availability, and personal preferences.

9). Comparison Between AAC Block And Red Clay Brick.

i). Cost Saving comparison

i). AAC blocks do not require any pre-curing. AAC block masonry joints are air-cured and need not require any curing. Infrastructure and labor involved in the curing process can be eliminated.

While,

Red Clay Bricks have to be soaked in water before using them in work. Moreover, 7-day curing has to be done on brickwork. This requires setting up of curing infrastructure, and tabor involvement.

ii). AAC Block can save substantial labor costs incurred for mortar mixing and conveying.

Whereas,

Red Clay Bricks have extra labor cost involvement for mortar mixing and conveying.

iii). AAC blocks are supplied in pellets and can be easily lifted and conveyed to the work spots using cranes and towers directly from the trucks. Saves labor involvement in unloading, conveying, and lifting. Less handling generates zero wastage.

Whereas,

Red Clay Bricks are supplied in loose and are unloaded & conveyed manually to different places. They have to be filled in buckets before lifting to heights and involve lots of labor. Bricks shifting and conveying involve a lot of labor and generate a huge amount of wastage.

iv). AAC blocks got fewer mortar joints of 3-5 mm thickness this can save substantially in terms of jointing material.

Whereas,

Red Clay Brick masonry generates a 3-4 times higher number of joints of 12 mm thickness.

ii). Construction speed comparison

i). AAC blocks are factory-made and posse’s dimensional accuracy. So they are easy to place, plumb, and level.

Whereas,

Red bricks are locally made and are irregular with less dimensional accuracy. Bricks are very difficult to place, level, and plumb.

ii). AAC block got fewer joints and hence construction speed is high.

Whereas,

Red Brick got a larger number of joints (4 times) in comparison with AAC blocks and hence construction speed is drastically reduced.

iii). AAC blocks cover a larger area.

Whereas,

Red Clay Bricks cover less area.

iv). AAC blocks can even be placed with semiskilled workers due to their dimensional accuracy and shape.

Whereas,

Red Clay Bricks work can be done with the help of a skilled mason only, due to the inaccuracy and shape issues.

v). AAC blocks mostly use block adhesive for bonding and are available in ready-mix packs. The thickness of mortar joints ranges between 3-5 mm.

Whereas,

Red Clay Brickwork is done by site mixed mortar and has to be a minimum of 10 mm. The mortar thickness is high in the case of Red Clay brickwork.

Conclusion

The choice between (Autoclaved Aerated Concrete) AAC block and red clay bricks ultimately depends on various factors, including the specific requirements of the project, local availability, cost considerations, and personal preferences. Both AAC block and red clay bricks have their own advantages and disadvantages, so it’s essential to assess them before making a decision.

AAC blocks are lightweight, precast concrete blocks that are manufactured with a combination of cement, lime, sand, and aluminum powder. They are known for their excellent thermal insulation properties, high strength, and fire resistance. AAC blocks are larger in size than traditional bricks, which reduces the number of joints in construction, leading to faster installation.

Related Video:- AAC Block and Red Clay Bricks

They also have good sound insulation properties. Additionally, AAC blocks are eco-friendly as they use fly ash, a waste product from thermal power plants, in their manufacturing process. However, AAC blocks may be more expensive than red clay bricks, and their availability might be limited in certain regions.

On the other hand, red clay bricks are made from natural clay that is molded and fired in kilns. They have been used for centuries and are known for their durability and strength. Red clay bricks are readily available in most regions, making them a convenient choice. They have good thermal mass, which helps regulate the temperature inside buildings, and they provide good sound insulation. Red clay bricks are also relatively cost-effective compared to AAC blocks.

However, they are heavier and require more mortar, which can increase construction time and costs. Additionally, red clay bricks have lower thermal insulation properties compared to AAC blocks.

In conclusion, if thermal insulation, lightweight construction, and faster installation are important considerations, AAC blocks could be a suitable choice. They offer excellent thermal properties, high strength, and fire resistance. On the other hand, if cost-effectiveness and availability are the primary factors, red clay bricks may be more suitable. They have a long history of use, durability, and relatively lower costs. It’s important to evaluate these factors based on your specific project requirements and consult with local experts or professionals to make an informed decision.

Bar Bending Schedule (BBS) Basics Part -1

This Ebook is specially designed for Freshers Civil Engineers. Recommended for Quantity Surveyors & Billing Engineers. Here You Can Learn All Basic Concepts & Formulas for Bar Bending schedules (BBS).

I hope this information can be useful for you guys.

If you like this article then please share it with your friends & also like our Facebook Page and join our Telegram Channel.

If you want a PDF copy of this, Do let’s know by commenting & you can message us on our Instagram & telegram channel, or you can download it from the top right-hand corner of this post.

Thanks For the Great Attention!

Good Bye & Take Care

Happy Learning

Also, Read,

All About AAC Block – An Ultimate Guide

Advantages And Disadvantages Of AAC Blocks

Construction Cost of a 1000 sqft Slab in India

Related Video

It’s actually a great and helpful piece of information. I’m glad that you just shared this helpful information with us. Please stay us informed like this. Thank you for sharing.