Before diving into the bar bending schedule of one-way slabs it’s important to understand what slabs are in the context of construction. Slabs are horizontal, flat structural members that are used to provide a stable surface for floors, roofs, and ceilings.

Slabs play a crucial role in the overall structural integrity of a building. They distribute the weight of the structure and any applied loads evenly, ensuring stability and support. Depending on the design and specific requirements of the project, different types of slabs are used, such as one-way slabs and two-way slabs.

What is a One Way Slab?

A one-way slab, also known as a simply supported slab, is a type of slab that is supported on two opposite sides by beams or walls. The main reinforcement in a one-way slab runs in only one direction, usually along the shorter span of the slab.

Key Features of a One Way Slab:

- Supported on two opposite sides by beams or walls

- Main reinforcement runs in one direction, typically along the shorter span

- Suitable for smaller spans and lighter loads

- Economical choice for residential buildings

- Efficient load transfer in a single direction

What is a Two-Way Slab?

A two-way slab, also known as a flat slab, is a type of slab that is supported on all four sides by beams or walls. Unlike a one-way slab, the main reinforcement in a two-way slab runs in both directions, along both the longer and shorter spans of the slab.

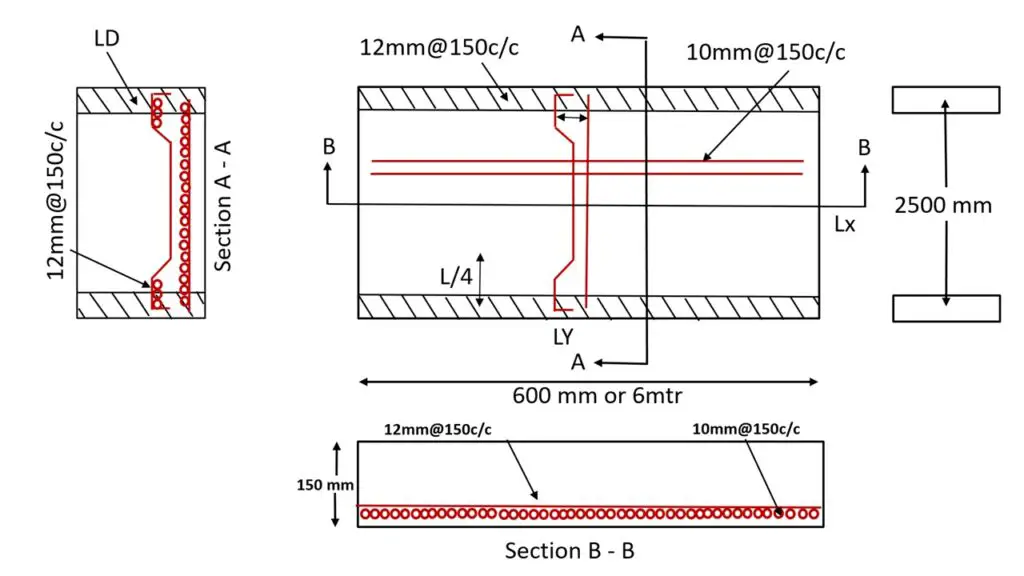

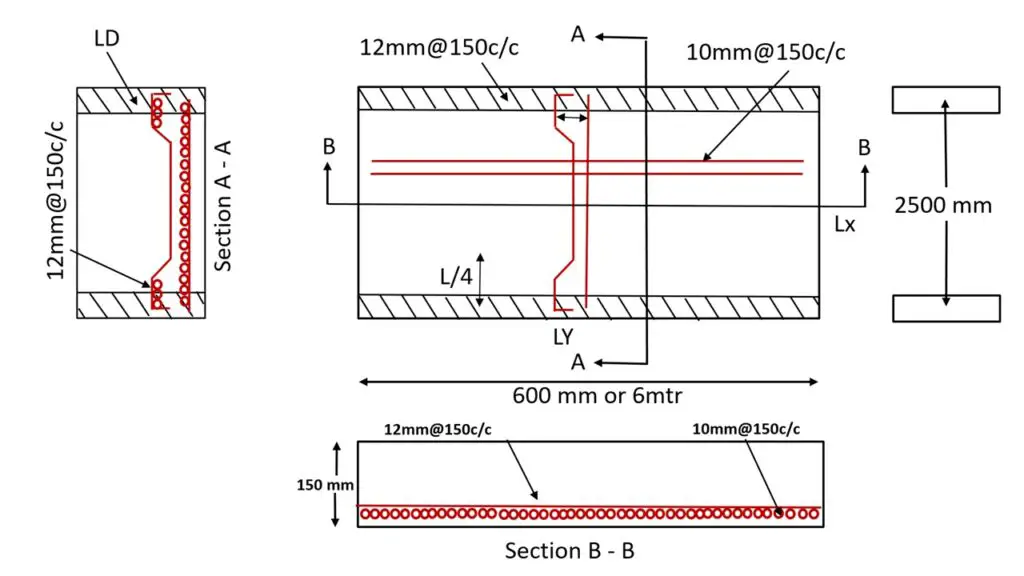

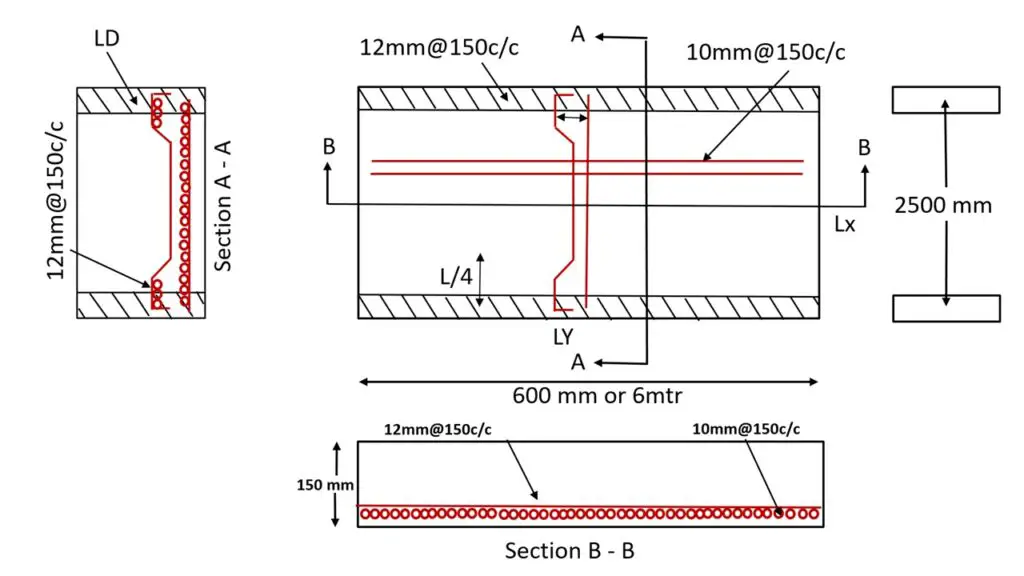

One-Way Slab – Bar Bending Schedule

Given Data,

Main Bar – 12mm

Distribution Bar – 10mm

Spacing – 150mm or 6”

Top & Bottom cover – 25mm

consider, Development length (Ld) -40d

The thickness of Slab – 150mm or 6”

No. of Bars Calculations,

No. of bars formula – (length of slab/Spacing) + 1

a). No. Of Main Bars

= Ly/spacing + 1

= (6000/150) + 1 = 41Nos.

Crank bar – 21Nos.

Straight bars – 20Nos.

b). No. Of Distribution Bars

= Lx/spacing + 1

= (2500/150) + 1 = 17Nos.

Cutting length calculations,

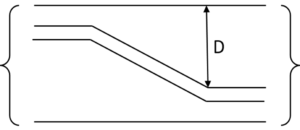

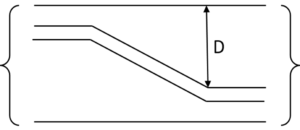

1 (a). Cutting length of Main Bars (crank)

Formula – Clear span of slab (Lx) + (2 x development length) + (2 x inclined length) – (45° Bend x 4) – (90° Bend x 2)

Inclined Crank Length L = 0.42D

Cutting length of main bar (crank) – 2500 + (2 x 40d) + (2 x 0.42D) – ( 1d x 4) – (2d x 2)

= 2500 + (2 x 40 x 12) + (2 x 0.42D) – (1 x 12 x 4) – ( 2 x 12 x 2)

= 2500 + 960 + (2 x 0.42D) – 48 -48

D = Slab thickness – 2 sides clear cover – diameter of bars = 150 – 50 -12 = 88mm So, D = 88mm |

= 2500 + 960 +(2 x 0.42 x 880 – 96

= 3400 + 73.92 – 96

3437.92mm or 3.437mtr.

Cutting length of main bars (crank) -3.437m

For 21 No. of bars – 21 x 3.437 = 72.177mtr.

Weight of steel – D x D/162 x (L)

= 12 x 12/162 x (72.177)

= 0.89 x 72.177 = 64.23Kg

1 (b). Cutting length of Main Bars (Straight)

Formula – Clear span of slab (Lx) + (2 x development length)

= 2500 = (2 x 40D)

= 2500 = (2 x 40 x 12)

= 2500 + 960 = 3460mm or 3.46mtr.

For 20 No. of bars – 20 x 3.46 = 69.2mtr.

Weight of steel – D x D/162 x (L)

= 12 x 12/162 x (69.2)

= 0.89 x 69.2 = 61.58Kg

2). Cutting length of Main Bars (crank)

Formula = Length of slab (Ly) – Covers on both sides

= 6000 – 50 = 5950mm or 5.95mtr.

For 17 Nos. of bars = 17 x 5.95 = 101.15Mtr.

Weight of Steel = D x D/162 x (L)

= (10 x 10 /162) x (101.15) = 0.61 x 101.15

= 61.70Kg

3). Extra Top Bars

Formula = (Lx/4)/Spacing + 1

= 2500 / (4 x 150) + 1 = 5Nos.

For 2 sides = 2 x 5 = 10Nos.

Length of Extra Top Bars = Length of top bars will be same as of distribution bars

= 5.95mtr.

For 10Nos. of bars = 10 x 5.95 = 59.5Mtr.

Weight of steel = 0.89 x 59.5 = 52.95Kg

Total Weight of Steel = 64.23 + 61.58 + 61.70 + 52.95

= 240.46Kg

|

So, the Total weight of Steel = 240.46Kg |

6 Important differenecs between one way slab and two way slab

i). Structural Distinctions

One of the key differences between one way slab and two way slab is their structural behavior. One way slabs primarily transfer their loads in one direction, while two way slabs distribute their loads in both directions.

ii). Load Distribution

In a one way slab, the load is distributed along the span that is perpendicular to the direction of the main reinforcement. In a two way slab, the load is distributed both along the longer and shorter spans, resulting in a more uniform load distribution.

iii). Span-to-Depth Ratio

The span-to-depth ratio is an important factor in slab design. One way slabs typically have a higher span-to-depth ratio compared to two way slabs. This is because one way slabs rely more on bending resistance provided by their main reinforcement.

iv). Construction Process

The construction process for one way slabs and two way slabs may differ slightly. One way slabs often require formwork and support beams along the edges to ensure proper load transfer. Two way slabs, on the other hand, may require additional reinforcement in the form of drop panels or column capitals.

v). Applications and Uses

One-Way Slab are commonly used in buildings where the spans are relatively shorter, such as residential houses. Two way slabs are more suitable for larger spans, such as in commercial or industrial buildings.

vi). Strength and Deflection

Due to their structural differences, one way slabs and two way slabs exhibit varying strengths and deflection characteristics. One-Way Slab may have higher bending moments and deflections, while two way slabs provide better resistance against cracking and deflection.

Conclusion

In conclusion, the choice between a One-Way Slab and a two way slab depends on factors such as span length, load requirements, and specific structural considerations. Understanding the differences between these two types of slabs is crucial in ensuring the structural integrity and functionality of a building.

Also, Read

Bar Bending Schedule (BBS) – Basic

Compound Wall Cost Per Rft & Sqft

For More Updates Like Our Facebook Page

Thanks & Good Bye

One-way slab BBS Video