Welcome to our guide on prestressed concrete – a revolutionary construction material that has transformed the way we build. At its core, prestressed concrete is similar to traditional concrete in terms of composition and production methods. However, what sets prestressed concrete apart is the pre-stressing process that enhances its strength and durability.

In pre-stressing, high-strength steel strands or tendons are stretched within the concrete before it cures, which creates a balancing compression force that neutralizes any tension that the structure may experience. This process results in a material that can support greater loads and resist deformation more effectively than traditional concrete.

Prestressed concrete is widely used in major infrastructure projects such as bridges, buildings, and dams, and is increasingly popular in India as a cost-effective and efficient construction solution. Let’s explore it further!

Key Takeaways:

- This concrete is a construction material that is strengthened through the process of pre-stressing.

- Pre-stressing involves high-strength steel strands or tendons being stretched within the concrete before it cures, resulting in a material that can resist deformation and support greater loads.

- This concrete is widely used in major infrastructure projects such as bridges, buildings, and dams, and is popular in India for its cost-effectiveness and efficiency.

Why is Prestressed Concrete Required?

In traditional concrete structures, the material is subjected to tensile forces that can lead to cracks, weakening the structure’s overall integrity. This is where prestressed concrete comes in. By introducing compressive stresses before applying external loads, our structures become more durable, stronger, and longer-lasting. The compressed concrete can resist the tension force during service life, which makes it a great option for use in high-stress environments. Through this method, we can construct more efficient and robust structures to withstand significant loads.

These concrete structures are less prone to cracking, corrosion, and deformation, as they offer improved resistance to external forces, whether caused by natural disasters or heavy loads. This is particularly important in India, where natural disasters such as earthquakes and floods pose significant risks to infrastructure.

Additionally, This concrete also offers more design flexibility, allowing us to construct structures with longer spans and reduced deformations. This can be achieved with reduced cross-sectional areas and less labor, leading to lower construction costs.

“Prestressed concrete is an innovative construction solution that offers unmatched performance and structural strength. By using high-strength materials and advanced design techniques, we can create structures that stand the test of time.”

Types of Prestressed Concrete

At its core, This concrete is designed to handle the compression forces required to counter external loads placed upon it. Let’s explore the various types of prestressed concrete systems and techniques used in construction:

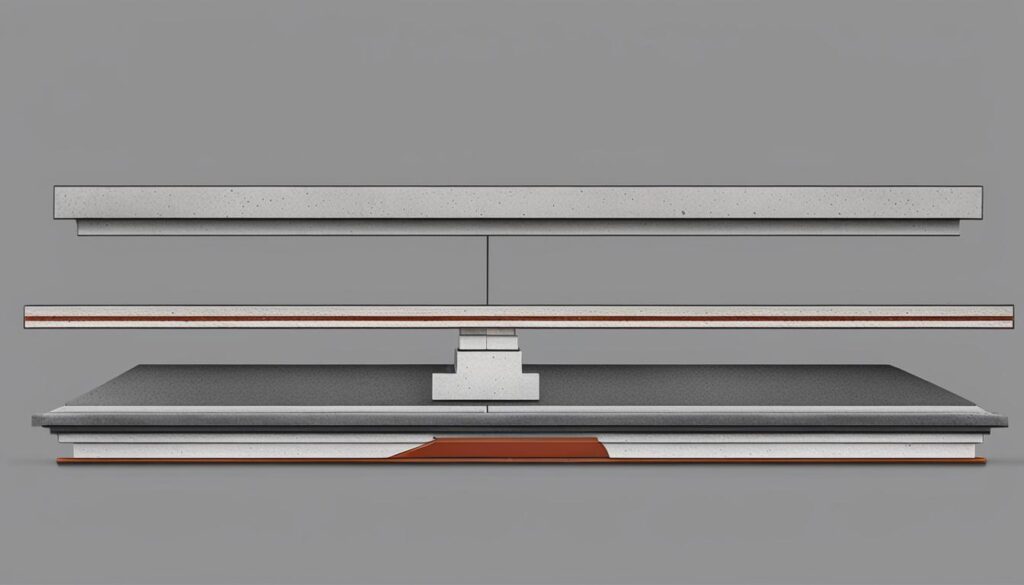

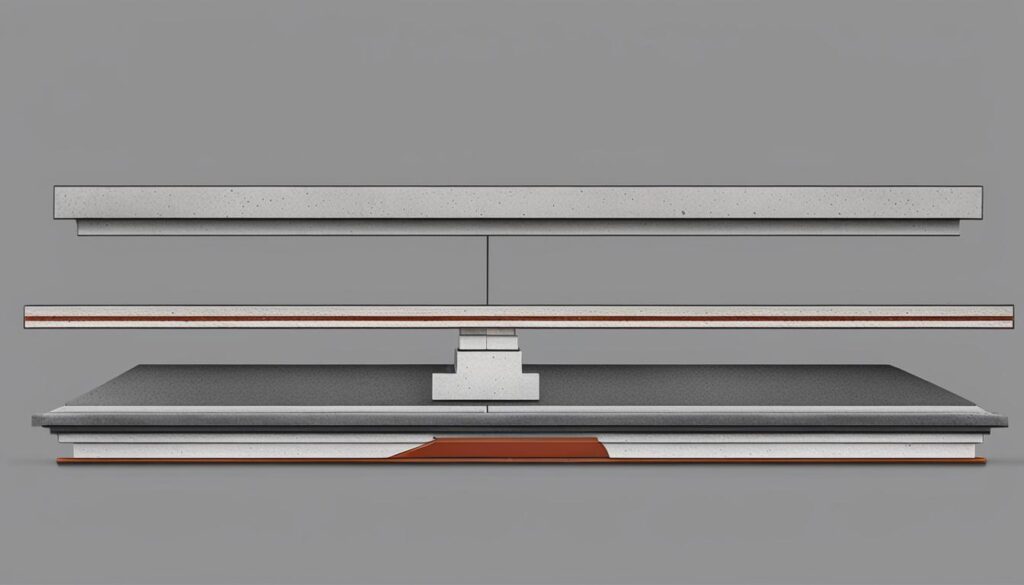

Pre-Tensioned Prestressed Concrete

Pre-tensioning is a process where high-strength steel strands or cables are tensioned between anchorages before pouring the concrete. The concrete is then cast around the stressed steel, enveloping it in compression. This technique is ideal for mass production of precast concrete components that can be used in construction projects.

Post-Tensioned Prestressed Concrete

In post-tensioning, the steel strands or cables are tensioned after the concrete has been poured and has attained sufficient strength. The anchorages are then fixed onto the concrete. This method allows for a more flexible design and can accommodate complex geometries, providing excellent durability and resistance.

Both pre-tensioned and post-tensioned concrete have unique advantages, like faster installation, flexibility, increased strength, and durability in harsh climates. By carrying out a thorough analysis of the project requirements, it is possible to determine the best type of prestressed concrete system that meets the specific project needs.

Pre-Stressed Concrete Materials

The choice of materials used in pre-stressed concrete construction is critical in our quest to build stronger and more durable structures. Our team utilizes only the highest quality materials, including high-strength steel strands, tendons, and specialized concrete mixtures that meet or exceed relevant standards.

The steel strands used in pre-stressed concrete construction are incredibly strong, with tensile strength ranging from 270 kN to 1860 kN. These strands are made of seven high-strength wires twisted together and coated with a protective layer to prevent corrosion. Our team carefully selects the appropriate steel strands with the required strength and durability to ensure optimal performance and reliability.

The tendons used in pre-stressed concrete construction are typically made of multiple steel strands. The tendons are anchored at one end of the structure, and then the concrete is poured around the tendon. Once the concrete has hardened, the tendons are tensioned, creating a compressive force in the concrete. Our team follows strict procedures for tensioning the tendons to achieve optimal stress distribution and load resistance.

The concrete mixture used in pre-stressed concrete construction is also critical in ensuring strength and durability. Our team selects high-strength concrete mixtures that contain supplementary cementitious materials, such as fly ash or slag, to enhance the strength and performance of the final product. The concrete mixture is designed to achieve a high compressive strength while remaining workable during construction.

The materials used in pre-stressed concrete construction must be carefully selected and interwoven to withstand the test of time. Our team’s commitment to quality materials, combined with our expertise in construction techniques, ensures that our pre-stressed concrete structures are not only strong and durable but also efficient and cost-effective.

Advantages and Disadvantages of Prestressed Concrete

At our construction firm, we believe that one of the biggest advantages of using these types of concrete is its enhanced strength and durability. When compared to traditional reinforced concrete, the use of high-tensile strength steel and the pre-stressing process allows for significant reductions in fatigue and deformation, resulting in structures that can withstand heavy loads and high traffic.

In addition to its strength, This concrete also offers several cost-effective benefits. By using precast concrete elements, constructions can be completed more quickly and efficiently, saving time and labor expenses. Using a more durable structure also means a reduced need for repairs and replacements, which can generate substantial cost savings over time.

However, it’s important to note that there are also some disadvantages to using this type of concrete. One potential drawback is that it requires more specialized knowledge and expertise to design, construct, and maintain than traditional concrete. Additionally, the high-tensile strength steel and pre-stressing procedures add to the overall cost of the construction process.

Overall, while there are both advantages and disadvantages to using this type of concrete in construction, we believe that its numerous benefits and advantages make it a worthwhile investment for any major infrastructure project.

IS Code for Prestressed Concrete

At this stage, we want to familiarize you with the Indian Standard (IS) code for prestressed concrete. Following these guidelines and specifications is crucial for the successful implementation and construction of this type of structure in India.

The IS Code has several sections and subsections, each addressing different aspects of this type of concrete design and construction, including materials, load balancing, and anchorage. As a team, we pride ourselves on possessing a thorough understanding of the IS Code and its requirements, ensuring that our projects are always in compliance with regulatory standards.

Key Guidelines and Specifications

Some key guidelines and specifications of the IS Code for prestressed concrete include:

| Topic | Guidelines |

|---|---|

| High-Strength Steel Strands | The minimum specified tensile strength is 1700 N/mm2. The strand should have a uniform cross-section and be free from visible defects. |

| Concrete Mix Design | Concrete should have a minimum 28-day compressive strength of 50 N/mm2. The minimum cement content should be 360 kg/m3, with a maximum water-cement ratio of 0.45. |

| Anchorages | Anchorages should have sufficient capacity to anchor prestressing steel and be designed to resist the transfer of forces between steel and concrete without damaging the tendons. |

| Grouting | Grouting should be done within 24 hours of prestressing. All air and water should be removed from the duct before grouting. |

We understand the importance of adhering to the IS Code for prestressed concrete, and our team follows all relevant guidelines and specifications to ensure safe, reliable, and long-lasting structures.

Prestressed Concrete Problems and Solutions

This concrete is a highly reliable construction solution, but like any other construction technique, it can also pose challenges during implementation. Common problems include tendon corrosion, anchorages, and concrete cracking. These issues can compromise the strength and long-term performance of this type of concrete structure, leading to potential safety hazards and costly repairs.

However, by employing effective solutions, these problems can be mitigated and prevented. Regular inspections, early detection of problems, and prompt remedial measures are crucial to ensuring the durability and strength of this type of concrete construction.

Tendon Corrosion

Tendons, which are crucial components of this type of concrete construction, are vulnerable to corrosion. Corrosion can lead to tendon failure, which can, in turn, lead to structural failures. The primary causes of tendon corrosion are exposure to moisture and other corrosive elements.

To prevent tendon corrosion, it is essential to ensure the proper sealing of tendons and keep them dry. Proper grouting and the use of corrosion inhibitors in the concrete mix can also mitigate the risk of corrosion.

Anchorages

Anchorages are critical parts of the prestressed concrete system, transferring the prestressing force from the tendons to the concrete. However, poorly designed or installed anchorages can lead to increased stress concentrations, leading to local failures and deficiencies in the entire system.

To mitigate anchorage problems, it is crucial to adhere to proper design and installation guidelines, regular inspections, and maintenance checks. Additionally, anchorages must be properly sealed to prevent moisture accumulation and corrosion.

Concrete Cracking

Concrete cracking can occur in prestressed concrete structures due to various reasons, such as excess loading, improper curing, and temperature fluctuations. Cracks can lead to reduced structural integrity, water infiltration, and environmental degradation.

To prevent concrete cracking, it is essential to ensure proper curing and use of high-quality concrete mixtures. Additionally, it is crucial to maintain prestress levels within recommended limits and employ appropriate design and construction techniques to reduce stress concentration.

By addressing these common problems with effective solutions, we can ensure the optimal performance and longevity of prestressed concrete structures, providing safe and reliable solutions for India’s infrastructure needs.

Applications of Prestressed Concrete

At this point, we have seen the benefits of prestressed concrete and its different types. Now, let’s take a look at how this construction material is used in various applications.this type of concrete adaptability and superior strength make it a prime choice for a wide range of infrastructure projects, including:

Bridges

Prestressed concrete is widely used in bridges due to its durability and strength. The use of pre-tensioned concrete beams ensures that bridge decks can withstand heavy loads, impacts, and vibrations over an extended period. These features make prestressed concrete bridges the best option for highways, flyovers, and railway bridges.

Buildings

In building construction, prestressed concrete is used for high-rise buildings that require a lot of load-bearing support. The material can resist compressive and tensile forces, making it suitable for tall structures that need additional stability against high winds and other environmental threats. Parking garages, apartments, commercial buildings, and other multi-story structures benefit from using prestressed concrete.

Dams

Prestressed concrete is also an excellent choice for building dams. Its high stiffness and strength enable these structures to resist the water pressure they face while holding back water. The tension in the prestressed cables inside the concrete elements also supports water pressure in the direction of the cables, maintaining a proper balance. The suitable applications of prestressed concrete in dams include servicing spillways, large spillway piers for arch dams, and canal linings.

Other Infrastructure Projects

Prestressed concrete is a versatile material that can be used for an extensive range of infrastructure projects, including tunnels, nuclear power stations, jetties, airports, and many others. Precast concrete elements, such as sleepers and track bearers in rail infrastructure, also use prestressed concrete, improving the operational efficiency and safety of rail services.

In conclusion, the applications of prestressed concrete are diverse and essential in producing robust, long-lasting infrastructure elements. Its superior strength, adaptability, and longevity place it squarely at the forefront of modern construction techniques.

Load Balancing Concept in Prestressed Concrete

At the heart of prestressed concrete is the concept of load balancing. By introducing a controlled level of compressive stress into the concrete, we can redistribute the loads and optimize the structural performance and efficiency.

This load-balancing process is achieved through either pre-tensioning or post-tensioning techniques. In pre-tensioning, the high-strength steel strands or tendons are tensioned before pouring the concrete, which allows the structural elements to deflect less under loading. In post-tensioning, the tendons are tensioned after the concrete has been poured and allowed to cure, which allows for the adjustment of the prestressing force to match the actual loads.

Both methods have their benefits and drawbacks, and choosing the right technique depends on various factors, including the type of structure, loads, and desired performance.

“By optimizing the load distribution and stress in the structures, prestressed concrete can improve the efficiency and longevity of bridges, buildings, and other infrastructure projects.”

Principles of Prestressed Concrete

At the heart of prestressed concrete lies a set of guiding principles that enable us to design and construct structures that are stronger, more durable, and more reliable than ever before. The principles of prestressed concrete are rooted in preloading, whereby we introduce initial stresses to the concrete before it is loaded with additional stresses from external loads.

This initial stress is introduced through the use of steel strands or tendons that are stretched and anchored to the concrete, inducing compression that offsets the tensile stress from the external loads. This process creates a balanced internal force system that minimizes cracking, deflections, and other forms of structural damage.

The key principles of prestressed concrete design include:

- Load balancing: The process of distributing the loads in a structure in such a way that the stresses and strains are evenly distributed.

- Initial stress: Introducing an initial stress into the concrete to create a balance of forces.

- Prestress: The force that is applied to the pre-stressed steel strands or tendons.

- Losses: The loss of strain due to factors such as creep, shrinkage, and relaxation of the steel strands.

- Design considerations: Ensuring that the design of the prestressed concrete structure is safe, efficient, and appropriate for its intended use.

By following these principles, we can create robust and resilient concrete structures that can withstand the challenges of time and the environment. The benefits of prestressed concrete are clear, from enhanced strength and durability to reduced maintenance and cost savings over the long term.

Transmission Length in Prestressed Concrete

When it comes to prestressed concrete, one crucial concept that needs attention is transmission length. This refers to the distance that prestress force can be transferred from the end of a tendon to the surrounding concrete.

The transmission length is dependent on several factors, including the bond between the tendon and concrete, the distance between the anchorage and the nearest point of compression, and the diameter of the steel strands. It is crucial to calculate and optimize the transmission length to ensure efficient and reliable transfer of load between the tendon and concrete.

At our company, we are aware of the importance of optimizing the transmission length for prestressed concrete structures. By utilizing the best materials and design techniques led by the latest available research, our projects are engineered to ensure the optimal transmission of prestress force.

“A good design must consider the transmission length of prestress force in prestressed concrete structures. A well-calculated transmission length leads to optimization of the prestress force distribution which leads to a safe and efficient prestressed concrete structure.”

-India Concrete Institute

Anchorage in Prestressed Concrete

At the heart of every prestressed concrete structure is an anchorage system that ensures the secure transfer of prestressing force from high-strength steel tendons to the concrete. Anchorage in prestressed concrete is crucial to delivering safe and reliable structures that can withstand the tests of time and nature.

There are different types of anchorages used in prestressed concrete construction, such as wedge anchors, mechanical anchors, and multi-wedge anchors. Each anchorage type has specific functions and applications that require careful consideration during the design and construction stages.

The anchorage system consists of several elements, including the anchor head, bearing plates, wedge, and concrete cone. The anchor head is responsible for pushing and pulling the tendon while the bearing plates distribute the force to the concrete. The wedge ensures the tight grip of the tendon, while the concrete cone acts as a protective layer and transfers the forces from the bearing plate to the concrete.

Best practices for anchorage in prestressed concrete include careful selection of anchorages based on project specifications, regular inspection and maintenance, and proper installation techniques. By following these best practices, we can ensure the long-term performance and durability of prestressed concrete structures in India and beyond.

Difference Between Reinforced Concrete and Prestressed Concrete

In construction, two primary materials are commonly used: reinforced concrete and prestressed concrete. Although both look similar, there are significant differences in their design, manufacturing process, and durability.

Reinforced concrete has steel reinforcement rods or mesh incorporated into its design to provide additional strength and load-bearing capacity. It is a widely used material for constructing building foundations, walls, and floors due to its low cost and easy availability. On the other hand, prestressed concrete uses high-strength steel strands or tendons that have been pre-tensioned to impart compressive stress. This pre-tensioning process helps to balance the loads and enhance the strength of concrete, ensuring greater durability and compatibility with large-scale construction projects.

Prestressed concrete structures are more durable, efficient, and safe than reinforced concrete systems. They can withstand higher loads and exert less stress on the surrounding soil. They require minimal maintenance, making them an ideal solution for long-lasting infrastructure projects such as bridges, dams, and high-rise buildings.

Comparison of Reinforced Concrete and Prestressed Concrete

| Parameter | Reinforced Concrete | Prestressed Concrete |

|---|---|---|

| Design Flexibility | Less flexible | More flexible |

| Strength | Lower strength | Higher strength |

| Load-Bearing Capacity | Less load-bearing capacity | More load-bearing capacity |

| Construction Time | Longer construction time | Shorter construction time |

| Maintenance | Requires maintenance | Less maintenance |

| Cost | Lower cost | Higher cost |

Overall, the difference between reinforced concrete and prestressed concrete lies in their performance and suitability for specific construction projects. While reinforced concrete offers cost advantages and is ideal for simple structures requiring lower loads, prestressed concrete provides greater strength, durability, and adaptability in more complex and extensive structures.

Design of Prestressed Concrete

At its core, the design of prestressed concrete is all about ensuring the safety and reliability of the structures we build. By using a specific set of design principles and calculations, we can create prestressed concrete structures that can handle immense loads and last for decades.

The design process starts with a thorough structural analysis, where we identify the loads that the structure will have to bear, including the self-weight of the structure, dead loads, live loads, wind loads, and seismic loads. This information is then used to calculate the required amount of prestressing force to counteract these loads and ensure that the structure is stable and secure.

Once we have determined the required prestressing force, we can begin to identify the optimal number and placement of tendons or reinforcement cables within the concrete structure. We take into account all design considerations and ensure that they are met, including curvature, creep, and loss of prestress.

Additionally, we must consider the type of concrete mixture used for the structure, and ensure that it is appropriately calculated and designed to accommodate the required prestressing force.

Throughout the design process, it is essential to consider all factors that can impact the final product and adjust the design as needed. By doing so, we can create prestressed concrete structures that are not only structurally sound but long-lasting as well.

The design of prestressed concrete is an exciting and challenging field that allows us to create structures that are strong, durable, and resilient.

“Design is not just what it looks like and feels like. The design is how it works.” – Steve Jobs

Conclusion

As we conclude our exploration of prestressed concrete, we cannot help but feel inspired by its revolutionary impact on construction. From bridges and buildings to dams and other infrastructure projects, prestressed concrete offers a reliable and long-lasting solution that enhances the strength and durability of structures.

By using high-strength steel strands, tendons, and concrete mixtures, we can achieve the desired structural integrity and performance. Pre-tensioned and post-tensioned prestressed concrete methods offer versatility and adaptability, making it a highly valuable construction solution in India and around the world.

Even with its advantages, it’s important to acknowledge potential drawbacks and challenges, but we can mitigate those issues by addressing common problems like tendon corrosion, anchorages, and concrete cracking and ensuring that design considerations are met.

We must follow the relevant guidelines and specifications outlined in the Indian Standard (IS) code for prestressed concrete to ensure the safe and efficient implementation of prestressed concrete structures. Careful consideration of load balancing and transmission length in the design and construction process optimizes structural performance and efficiency.

Overall, we believe that prestressed concrete will continue to revolutionize the construction industry, and we are excited to see what innovations and advancements lie ahead in this field. With its enhanced strength, durability, and cost-effectiveness, we can build a better future with prestressed concrete.

Thanks For the Great Attention!

Good Bye & Take Care

Happy Learning

Also, Read,

FAQ

What is prestressed concrete and how does it work?

Prestressed concrete is a construction material that incorporates tensile forces into the concrete to counteract the expected compressive forces. This process involves applying pre-compression to the concrete before loads are applied, resulting in enhanced structural strength, durability, and resistance to cracking and deformation.

Why is prestressed concrete required?

Prestressed concrete is required to overcome the limitations of traditional reinforced concrete. It provides increased load-bearing capacity, reduced material usage, and improved resistance to cracking and deflection. By introducing pre-compression, prestressed concrete ensures structures that can withstand heavy loads, long spans, and challenging environmental conditions.

What are the types of prestressed concrete?

There are mainly two types of prestressed concrete: pre-tensioned and post-tensioned. Pre-tensioned prestressed concrete involves tensioning the steel strands or tendons before casting the concrete, while post-tensioned prestressed concrete involves tensioning the steel elements after the concrete has been cast and hardened.

What materials are used in prestressed concrete construction?

Prestressed concrete utilizes high-strength steel strands or tendons, along with specially designed concrete mixtures. The steel strands or tendons provide tensile strength, while the concrete encases and protects them, ensuring compatibility and efficient transfer of forces between the materials.

What are the advantages and disadvantages of prestressed concrete?

Prestressed concrete offers several advantages, including higher load-bearing capacity, reduced material usage, improved structural performance, and increased resistance to cracking. However, it also has some disadvantages, such as higher initial costs, complexity in design and construction, and the need for skilled labor and specialized equipment.

What is the IS code for prestressed concrete?

The Indian Standard (IS) code for prestressed concrete is IS 1343: 2012. This code provides guidelines and specifications for the design and construction of prestressed concrete structures in India, ensuring safety, quality, and performance.

What are common problems in prestressed concrete and their solutions?

Common problems in prestressed concrete include tendon corrosion, anchorage failures, and concrete cracking. These issues can be addressed through preventive measures such as proper corrosion protection, regular inspections and maintenance, and using appropriate construction techniques and materials.

What are the applications of prestressed concrete?

Prestressed concrete is widely used in various applications, including bridges, buildings, dams, nuclear power plants, and offshore structures. Its versatility allows for the construction of long-span structures, high-rise buildings, and structures that require high load-bearing capacity and exceptional durability.

What is the load balancing concept in prestressed concrete?

The load balancing concept in prestressed concrete involves redistributing the applied loads to optimize the structural performance. This is achieved by applying pre-compression to the concrete, which transfers part of the load to the prestressed steel strands or tendons, resulting in a balanced load distribution and improved structural efficiency.

What are the principles of prestressed concrete?

The principles of prestressed concrete involve imparting an initial stress or pre-compression to the concrete to counteract the expected compressive forces. These principles include calculating the required prestressing force, considering losses, and designing the structure to ensure efficient load transfer and long-term performance.

What is the transmission length in prestressed concrete?

Transmission length in prestressed concrete refers to the distance required for the pre-compression forces to be effectively transmitted from the steel strands or tendons to the surrounding concrete. It is important to calculate and optimize the transmission length to ensure proper load transfer and structural performance.

What is the role of anchorage in prestressed concrete?

Anchorage systems in prestressed concrete are used to secure the steel strands or tendons in place, enabling the transfer of prestressing forces from the steel to the concrete. The design and installation of proper anchorage systems are crucial for ensuring the safe and reliable transfer of forces and maintaining the integrity of the structure.

What is the difference between reinforced concrete and prestressed concrete?

The main difference between reinforced concrete and prestressed concrete lies in the way they handle tensile forces. Reinforced concrete uses steel reinforcement to resist tensile forces, while prestressed concrete incorporates pre-compression to induce tensile forces and counteract the expected compressive forces. This difference allows prestressed concrete to achieve higher load-bearing capacity and improved performance compared to reinforced concrete.

What is the design process of prestressed concrete?

The design process of prestressed concrete involves structural analysis, calculation of required prestressing force, consideration of losses, and determining the most appropriate prestressing system and anchorage details. It also includes ensuring compatibility between the prestressed steel strands or tendons and the concrete, as well as considering other design considerations such as serviceability and durability.