Advantages And Disadvantages Of AAC Blocks

Autoclaved aerated concrete (AAC) blocks are a type of lightweight and highly insulating popular building material that is widely used in construction.

The manufacturing process involves combining cement, lime, water, and a small amount of aluminum powder to create a chemical reaction that forms millions of tiny air bubbles throughout the block. The resulting product is a durable and high-strength building material that has excellent insulation properties and is resistant to fire and moisture.

Like any other building material, AAC has numerous advantages & disadvantages over traditional building materials, making it an appealing choice for a wide range of construction projects, Here we’ll discuss 30 advantages and disadvantages of using AAC blocks in detail

Advantages Of AAC Block

1). Lightweight

The porous structure of AAC makes it significantly 3 to 4 times lighter than traditional bricks or concrete blocks. This makes transportation of AAC blocks both easier and more cost-effective. Additionally, This reduced weight translates to a lower overall load on a building’s structure, potentially reducing the need for reinforcement and enabling more flexible designs.

The use of AAC blocks reduces a building’s overall dead load by up to 60%, making it possible to construct taller buildings. The weight of an AAC block can vary between 9-12 kg, depending on the level of moisture present.

2). Strength

AAC blocks, or Autoclaved Aerated Concrete blocks, are known for their excellent strength and durability. Despite being lightweight, these blocks have a compressive strength that is comparable to that of traditional concrete blocks. As per IS:2185 part III – AAC blocks have a compressive strength of 3 – 4 N/mm2. making them suitable for load-bearing walls & give higher stability to the building structure.

3). Ease Of Workability & Design Flexibility

Due to its lightweight nature and the fact that it can be easily cut, drilled, and shaped to fit any design requirements. It allows for easy installation of electrical and plumbing systems. AAC blocks are simple to install and work with. This can lead to faster construction times and lower labor costs.

4). Blocks size

AAC blocks are available in various sizes to meet the diverse needs of construction projects. The most common sizes of AAC blocks are:

|

S.No. |

Particulars |

Size (L x B x H) in mm |

|

1 |

Size 1 |

600×200×75 |

|

2 |

Size 2 |

600×200×100 |

|

3 |

Size 3 |

600×200×150 |

|

4 |

Size 4 |

600×200×200 |

|

5 |

Size 5 |

625×240×75 |

|

6 |

Size 6 |

625×240×100 |

|

7 |

Size 7 |

625×240×150 |

|

8 |

Size 8 |

625×240×200 |

These sizes are widely used in the construction of walls, slabs, and other structural components. However, it is important to note that the availability of AAC block sizes may vary depending on the manufacturer and location.

It is always advisable to check with the manufacturer or supplier to determine the availability of specific sizes and quantities before placing an order.

5). Thermal Insulation

The air pockets within AAC provide excellent thermal and acoustic insulation, making it an energy-efficient choice for building construction. This can result in reduced energy consumption for heating and cooling, as well as a quieter indoor environment.

6). Fire Resistance

AAC blocks that are highly fire-resistant(up to 1600° C). They are non-combustible and can withstand high temperatures for extended periods, enhancing the fire safety of a building. This makes it an excellent material for fire-resistant construction and enhances the overall safety of a building.

7). Eco-Friendly

The production process of AAC generates less waste and uses fewer natural resources compared to traditional building materials. They are made from non-toxic materials and consume less energy during production, making them environmentally friendly. In addition, the energy efficiency of AAC structures can help reduce the overall environmental impact.

8). Earthquake-Resistant

AAC blocks offer excellent seismic performance, making them ideal for use in earthquake-prone areas. The lightweight nature of AAC blocks provides better resistance to earthquakes.

9). Pest-Resistant

AAC blocks are inorganic and do not support the growth of mold, fungi, or insects, making them ideal for use in areas prone to termite damage.

10). Fast Construction

AAC blocks are known for their fast construction properties, making them an ideal choice for construction projects that require a quick turnaround time. The lightweight nature of AAC blocks means that they can be easily transported and installed by just a few workers, reducing construction time and labor costs.

Overall, the fast construction properties of AAC blocks make them an excellent choice for construction projects that require speed and efficiency without compromising on quality or durability.

11). Reduced Structural Load

The lightweight nature of AAC blocks reduces the overall load on the building’s structure.

12). Precision And Uniformity

AAC blocks are manufactured to strict dimensional tolerances, ensuring precise construction and reducing waste. They have accurate dimensions and uniformity, ensuring a consistent quality of construction.

13). Reduced Construction Waste

The precision and uniformity of AAC blocks result in minimal waste during construction.

14). Moisture Resistance

AAC blocks have low water absorption, which means reducing the chances of dampness and water seepage. They are less likely to absorb moisture and cause damage.

15). Energy Efficiency

The thermal insulation properties of AAC blocks can help improve the energy efficiency of buildings, reducing energy consumption for heating, cooling, and costs.

16). Sound Insulation

AAC blocks offer excellent soundproofing & sound insulation properties, reducing noise transmission between rooms.

17). Non-Toxic

AAC blocks are non-toxic, making them safe for use in homes and buildings.

18). Versatile

AAC blocks can be used for a wide range of construction applications, including walls, floors, and roofs.

19). Long Lifespan

AAC blocks have a long lifespan and require minimal maintenance, reducing long-term costs.

20). Improved Indoor Air Quality

AAC blocks are made from natural materials and do not emit any harmful gases, which can improve indoor air quality.

21). Easy To Transport

AAC blocks are lightweight and can be transported in large quantities, reducing transportation costs.

22). Resistant To Weathering

AAC blocks are highly resistant to weathering and can withstand extreme temperatures, making them ideal for use in harsh environments.

23). Stable Dimensions

AAC blocks have stable dimensions, which means they do not expand or contract with changes in temperature and humidity.

24). Easy to plaster

AAC blocks are easy to plaster, reducing construction time and labor costs.

25). Reduced Carbon Footprint

AAC blocks require minimal energy to manufacture, reducing their carbon footprint.

26). Reduced Waste

AAC blocks generate minimal waste during production and can be recycled or reused.

27). Improved Indoor Comfort

AAC blocks offer excellent thermal insulation properties, which can improve indoor comfort.

28). Improved Indoor Humidity Control

AAC blocks offer excellent humidity control properties, reducing the risk of mold and mildew growth.

29). Enhanced Design Flexibility

AAC blocks can be easily customized to fit any design requirements.

30). Cost-Effective

The cost of AAC blocks may vary based on factors such as location, manufacturer, and size, they generally have a higher cost per unit compared to traditional red bricks.

However, despite the higher cost, AAC blocks can offer significant savings in terms of transportation, handling, and installation due to their lightweight nature. Additionally, AAC blocks have excellent insulation properties, which can help reduce energy costs over the life of the building.

Overall, while the cost of AAC blocks may be higher initially, their unique properties make them a cost-effective and sustainable building material in the long run. Despite their numerous advantages, AAC blocks are relatively affordable compared to other building materials.

Technical Specification Of AAC Blocks

AAC blocks are available in various sizes to meet the diverse needs of construction projects. The most common sizes of AAC blocks are:

|

S.No. |

Parameter |

Specification |

|

1 |

Density Oven Dry |

500 to 700 kg/m3 |

|

2 |

Shear Strength | 0.1 to 0.6 N/m2 |

|

3 |

Compressive strength |

3 to 4 N/mm2 (MPa) |

|

4 |

Modulus of Elasticity |

2040 Mpa |

|

5 |

Variation in dimensions |

+/-1mm |

|

6 |

Water Absorption |

10-12% |

|

7 |

Thermal Conductivity “K” |

0.16 – 0.18 W/(K-m) |

|

8 |

Drying Shrinkage |

0.04%-0.06% |

|

9 |

Sound Absorption |

0.35 to 0.60 |

|

10 |

Fire Resistant |

4 Hrs (for 200 mm wall) |

Uses Of AAC Blocks

AAC (Autoclaved Aerated Concrete) blocks are versatile building materials that can be used in a variety of construction projects. Here are some of the common uses of AAC blocks:

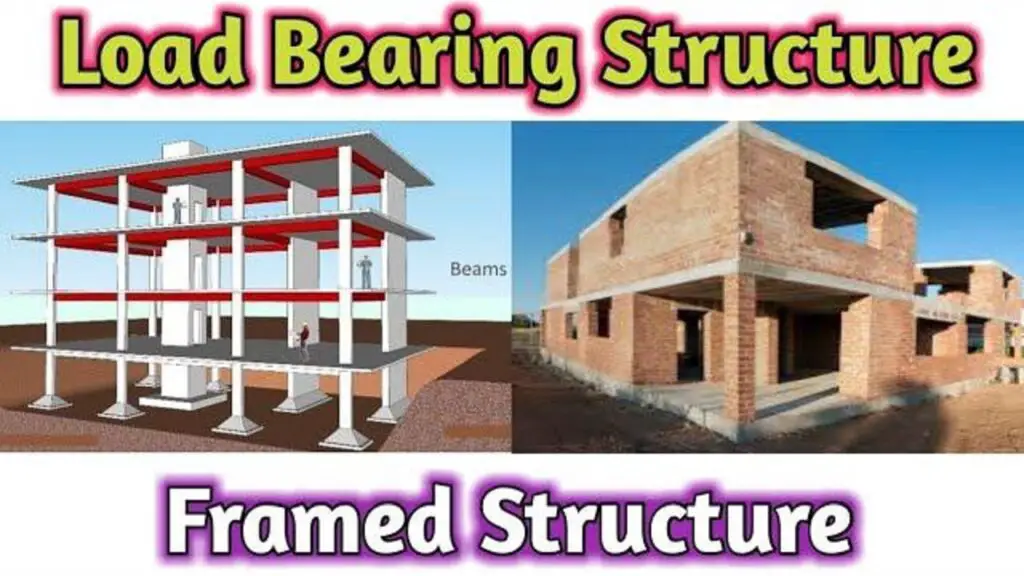

i). Load-bearing Walls: AAC blocks can be used to construct load-bearing walls due to their high compressive strength.

ii). Non-Load-bearing Walls: AAC blocks can also be used to construct non-load-bearing walls, such as partitions or infill walls.

iii). Floors and Roofs: AAC blocks can be used as a lightweight alternative to traditional concrete blocks or clay bricks for constructing floors and roofs.

iv). Firewalls: AAC blocks have excellent fire resistance properties and can be used to construct firewalls.

v). Sound Barriers: AAC blocks have good acoustic insulation properties and can be used as sound barriers in buildings located near highways or busy roads.

vi). Prefabricated Structures: AAC blocks can be used to construct prefabricated structures such as precast walls, precast slabs, and precast panels.

vii). Retaining Walls: AAC blocks can be used to construct retaining walls in landscaping and civil engineering projects.

viii). Cladding: AAC blocks can be used as cladding for buildings to improve their aesthetics and provide thermal insulation.

ix). Lintels and Beams: AAC blocks can be used to construct lintels and beams in buildings.

Disadvantages Of AAC Block

1). Initial Cost

The initial cost of AAC blocks is generally higher than that of traditional concrete blocks.

2). Limited Color Options

These blocks typically come in a limited range of colors, which may impact aesthetics.

3). Sealing And Finishing

Additional sealing and finishing treatments may be required to protect the blocks from moisture and UV damage.

4). Not Suitable For All Climates

AAC blocks may not perform well in extremely cold or wet climates without proper moisture management.

5). Susceptible To Damage

They can be more easily damaged during transport or handling compared to traditional concrete blocks.

6). Specialized Tools

Specialized tools may be needed to cut or shape the blocks, which can increase construction costs.

7). Lower Sound Insulation For Impact Noise

While they provide good sound insulation for airborne noise, they may not be as effective for impact noise.

8). May Require Additional Reinforcement

In some cases, additional reinforcement may be needed for load-bearing walls or other structural elements.

9). Limited Recycling Options

Unlike traditional concrete blocks, AAC blocks have limited recycling potential.

10). Long Curing Time

AAC blocks require a longer curing time compared to traditional concrete blocks, which may delay construction.

11). Susceptible To Freeze-Thaw Cycles

In cold climates, AAC blocks can be more susceptible to damage from freeze-thaw cycles if not properly protected.

12). Limited Availability

AAC blocks may not be readily available in all locations, making them more difficult to obtain and increasing construction costs.

13). Fragility

AAC blocks are relatively fragile and can easily break or crack during transport or installation.

14). Limited Strength

Although AAC blocks are strong, they may not be as strong as other building materials, such as concrete or brick.

15). Lower Tensile Strength

They have a lower tensile strength compared to traditional concrete blocks, which might limit their use in certain applications.

16). High Transportation Costs

Because AAC blocks are lightweight, they can take up a lot of space during transport, which can lead to high transportation costs.

17). Limited Availability Of Skilled Labor

The installation of AAC blocks may require skilled labor, which may not be readily available in all areas.

18). Limited Load-Bearing Capacity

AAC blocks may not have the same load-bearing capacity as other building materials, which can limit their use in certain applications. AAC blocks are suitable only for partition walls.

19). Limited Durability

While AAC blocks are durable, they may not last as long as other building materials, such as brick or stone.

20). Limited Resistance To High Winds

AAC blocks may not be as resistant to high winds as other building materials, which can limit their use in areas with high winds.

21). Difficulty With Retrofitting

Retrofitting existing structures with AAC blocks can be difficult and expensive.

22). Limited Availability Of Skilled Installers

The installation of AAC blocks may require specialized skills, which may not be readily available in all areas. Skilled labor is required for proper installation and construction with AAC blocks.

However, some drawbacks of AAC blocks include limited availability in certain regions, higher initial costs compared to traditional materials, and potential susceptibility to moisture damage if not adequately protected. Despite these limitations, AAC blocks are a popular choice in many construction projects due to their numerous benefits.

Bar Bending Schedule (BBS) Basics Part -1

This Ebook is specially designed for Freshers Civil Engineers. Recommended for Quantity Surveyors & Billing Engineers. Here You Can Learn All Basic Concepts & Formulas for Bar Bending schedules (BBS).

I hope this information can be useful for you guys.

If you like this article then please share it with your friends & also like our Facebook Page and join our Telegram Channel.

If you want a PDF copy of this, Do let’s know by commenting & you can message us on our Instagram & telegram channel, or you can download it from the top right-hand corner of this post.

Thanks For the Great Attention!

Good Bye & Take Care

Happy Learning

Also, Read,

All About AAC Block – An Ultimate Guide

AAC Blocks Manufacturing Process – An Ultimate Guide

How To Check The Quality of AAC Block

MDF VS Particle Board – 15 Important Differences

Flush Door vs Wooden Panel Door

Related Video

Wow! This could be one of the most useful blogs we’ve ever come across on thesubject. Basically fantastic post! I’m also a specialist in this topic therefore I can understand your hard work.